Fully Automatic 8 Head Pick and Place Machine DSQ800 LED Chip Mounter Machine With 120 Feeder Position

- Category: Electronics Production Machinery >>>

- Supplier: Wenzhou Hecan Electronic Equipment Co. Ltd.

Share on (1600380087130):

Product Overview

Description

Product Introduction

SMT Online 8 Heads Simultaneous Recognition Pick And Place Machine With 120 Feeders Positions

Introduction

1.Feeder Positions----120 PCS

Satisfy the mounting needs of various types of materials+Packaged components of various specifications

A:120 *8mm feeder stations, support 8/12/16/24/32/44mm NXT electric feeder +Vibration feeder + multiple IC trays

B:NXT electric platform, specifications:8mm-44mm NXT electric feeder

B:NXT electric platform, specifications:8mm-44mm NXT electric feeder

High efficiency, stable performance and long service life

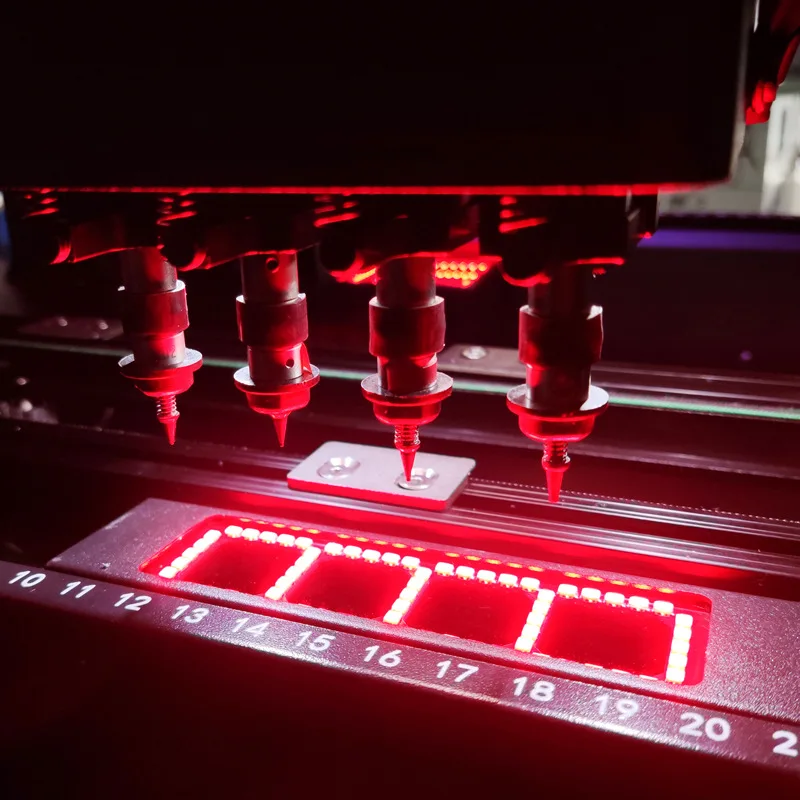

2.Independent placement heads-----8 PCS

Allocate various nozzles,Suitable for product placement requirements of more specification devices

A:Four mounting heads pick simultaneously on each of the left and right arms

Eight heads working at the same time, the efficiency of material taking is improved

Eight heads working at the same time, the efficiency of material taking is improved

B:The mounting head can be raised and lowered independently, 0-360 degree rotation,The maximum height of the applicable components can reach to 20mm

C:The Z-axis can rise and fall independently according to the thickness of the material.For the resistance and capacitance components, the mounting head can realize the fly visual identification.for high components can reduce speed and High placement mode operation

D:Can meet the different sizes of product components, specifications and packaging, achieve the diversity of a product device mounted at one time

3.Comprehensive efficiency :20000/CPH Maximum efficiency :26000/CPH

A:Mounting speed of various components(resistance, capacitance, chip):20000/CPH

B:Only capacitance or resistance or LED lamp mounting speed:26000/CPH

B:Only capacitance or resistance or LED lamp mounting speed:26000/CPH

4.High speed cameras*8, HD camera*1 ,Mark cameras*2

A:The high-speed camera can take visual pictures of devices with a diameter of less than 10mm, including resistor and capacitance, lamp bead, transistor, diode and so on

B:The HD camera meet the requirements of devices with a diameter of less than 35mm, mainly chips, pins, modules and other devices for visual photography

5.Resistance and capacitance above 0201, 0.3mm pins chip

B:The HD camera meet the requirements of devices with a diameter of less than 35mm, mainly chips, pins, modules and other devices for visual photography

5.Resistance and capacitance above 0201, 0.3mm pins chip

A:Use electric feeder to meet the minimum 0201 device mounting requirements.

B:HD camera accurate vision, meet the needs of QPF, BGA, QFP chip mounting

B:HD camera accurate vision, meet the needs of QPF, BGA, QFP chip mounting

6.PCB with thickness less than 3mm, size:350*330mm

A:Support the thickness of 1mm-3MM PCB board (including resin board, aluminum board, soft board, etc)

B:Support minimum PCB width : 50mm Maximum PCB width: 330mm Length :350mm

A:Support the thickness of 1mm-3MM PCB board (including resin board, aluminum board, soft board, etc)

B:Support minimum PCB width : 50mm Maximum PCB width: 330mm Length :350mm

Specification | ||

Model | HC-DSQ800 | |

Number of Placement Heads | 8(high-accuracy) | |

Number of iC Trays | 96 | |

Number of Feeders | 120(subject to 8mm feeder) | |

Positioning Accuracy | 0.01mm | |

Repeated Mounting Accuracy | 0.02mm | |

Range of Mounting Speed | 20000-26000/CPH | |

Applicable Components | Resistor/capacitor/chip/lamp bead etc | |

Supported Maximum Area of PCB | 350*330mm | |

Feeders | NXT electric feeder,vibration feeder,IC tray etc | |

Recognition Devices | Mark camera ----------------------2 High-precision camera -------1 Fast recognition camera -----8 | |

Maximum Height of Applicable Components | ≤20mm | |

Recognition Methods | Simultaneous recognition and picking with four heads | |

PCB Convey Mode | Three-stage entry, automatic connection from left to right, automatic PCB | |

Mark Positioning | Manual/ Automatic | |

Programming Method | Automatic programming after manually importing files of PCB coordinates | |

Control System | Control system of our own design | |

Maximum Step Lenqth of XY Axis | 423mm*734mm(Left) 423mm*734mm (Right) | |

Tracks of XY Axis | Four linear motion quide + four ground ball screw | |

Motion Mode of XY Axis | Intelligent linkage of acceleration and deceleration of curve and line, integrated linear interpolation algorithm. | |

Control Computer | Industrial control computer with Intel high-performance processorindustrial control computer with Intel high-performance processor | |

Adjusting Method of Tracks | Electric | |

Range of Nozzle Buffer | 4.5mm | |

Maximum Step length of Z Axis | 50mm | |

Maximum Step Length of Z Axis | Resistor/capacitor/chip/lamp bead etc | |

Range of Angle for Components | 士180° | |

Motor | Imported AC Servo Motor MINAS A6 series | |

Driver | Imported high-speed DSP driver | |

Air Supply Requirements | Oil water filter> 60L,dust filter and air pressure stabilizer etc | |

Vacuum Supply of Nozzle | Japanese CKD vacuum generator integrating the high.speed vacuum burst function | |

Range of Air Supply Pressure | 0.5-0.6mp | |

Vision Display | 17-inch industrial control display | |

Os | Independent research and development SMT intelligent OS based on Windows | |

Cable | German lgus durable flexible cable(10 million times) | |

Power Supply | 220V 50/60Hz | |

Average Power | 1500W | |

Machine Dimensions | 1740*1360*1440mm | |

Weight | 1100Kg | |

Machine details

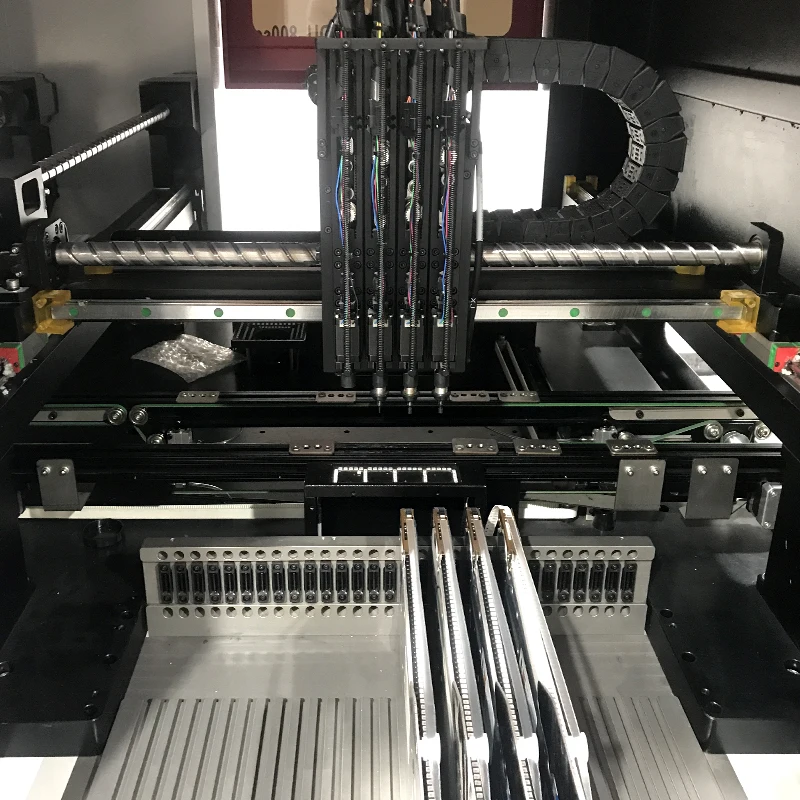

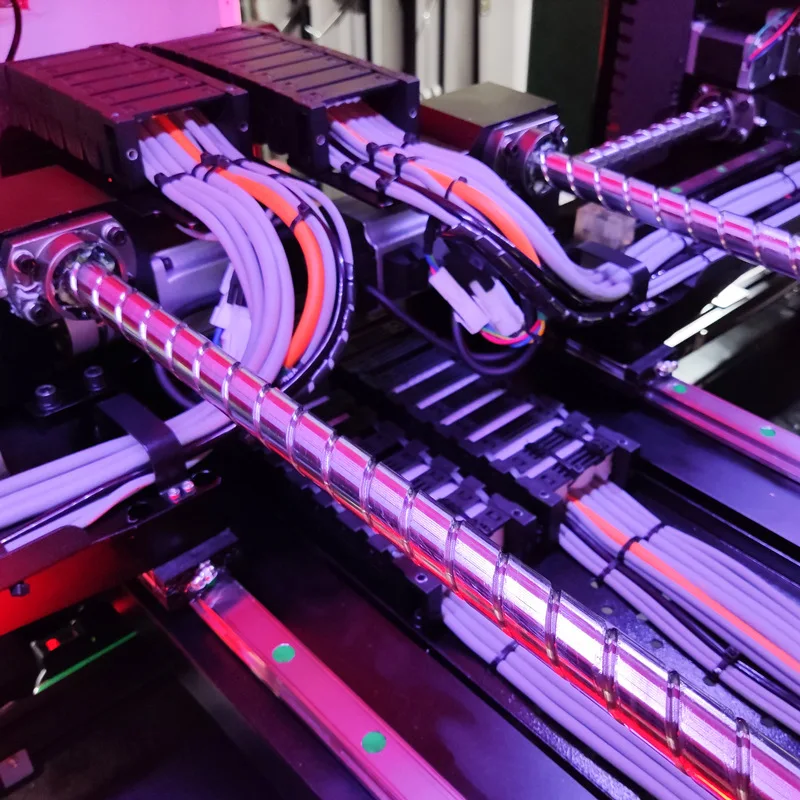

Inner part details

Stable Mounting Head

High speed Camera HD Camera

Imported AC Servo Motor

High Durable Cable Carrier and Flexible Cable

Precision Ball Screw and Linear Motion Guide

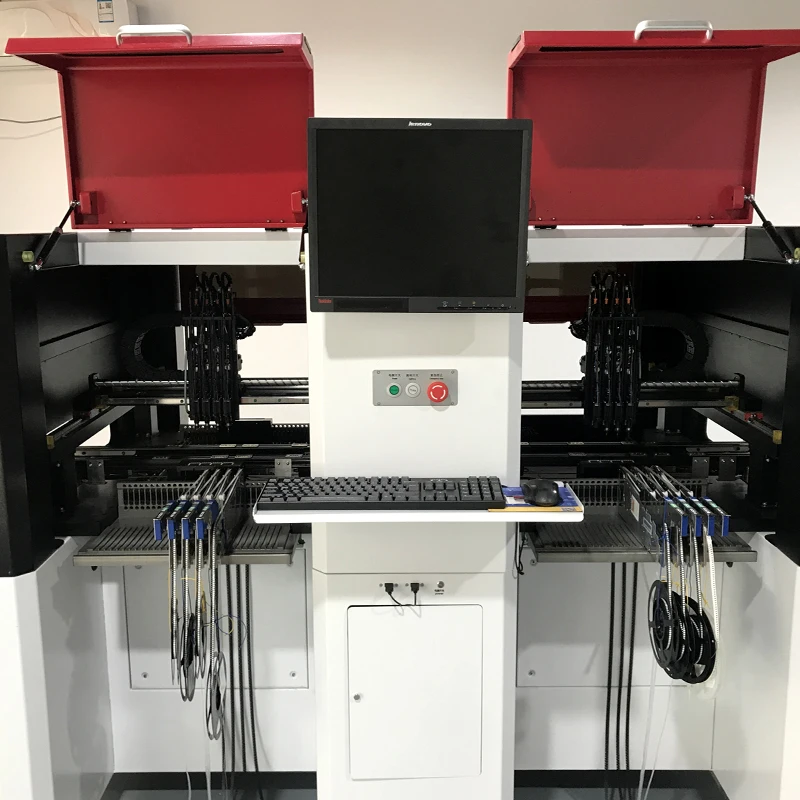

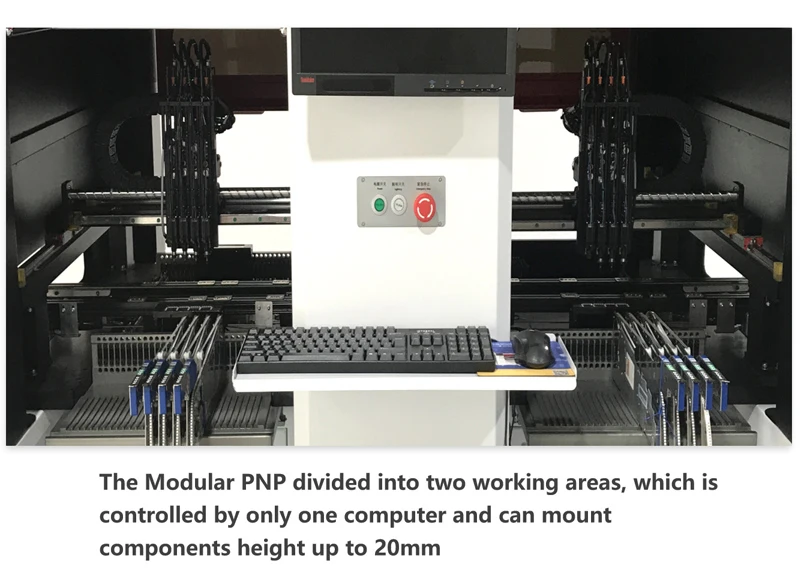

Working Areas

This model PNP MACHINE divided into 2 working areas

Controlled by only one computer and components within 20mm height can be picked well

Left+Right working area details

Workshop

Package

FAQ

Q:Does machine have quality certificate?

A:All of our machines have passed CE certificate,ISO14001(BCC),ISO9001(IQNET) and have own patent.

A:All of our machines have passed CE certificate,ISO14001(BCC),ISO9001(IQNET) and have own patent.

Q:The Warranty of the machine?

A:One year, the parts will be free for the buyer in the warranty.

A:One year, the parts will be free for the buyer in the warranty.

Q:Software version for these machines?

A:English version(keep updating)

A:English version(keep updating)

Q:Is it hard to learn/use these machines?

A:No, not hard at all.For our previous clients, just 2 days is enough to learn operating the machines.

A:No, not hard at all.For our previous clients, just 2 days is enough to learn operating the machines.

Q:How is the training?

A:After buying our machines, welcome to visit our factory to learn all.our engineers can go to our company or it is so easy to operate the machine according the training video and user manual, the user manual will come with the machine together.

A:After buying our machines, welcome to visit our factory to learn all.our engineers can go to our company or it is so easy to operate the machine according the training video and user manual, the user manual will come with the machine together.

If you wanna know more, feel free to contact me directly

Mail/Skype:smtmachines@hcpnp.com

Tel/Wechat/WhatsApp:+8618367786556/+8615858886852

We Recommend

New Arrivals

New products from manufacturers at wholesale prices