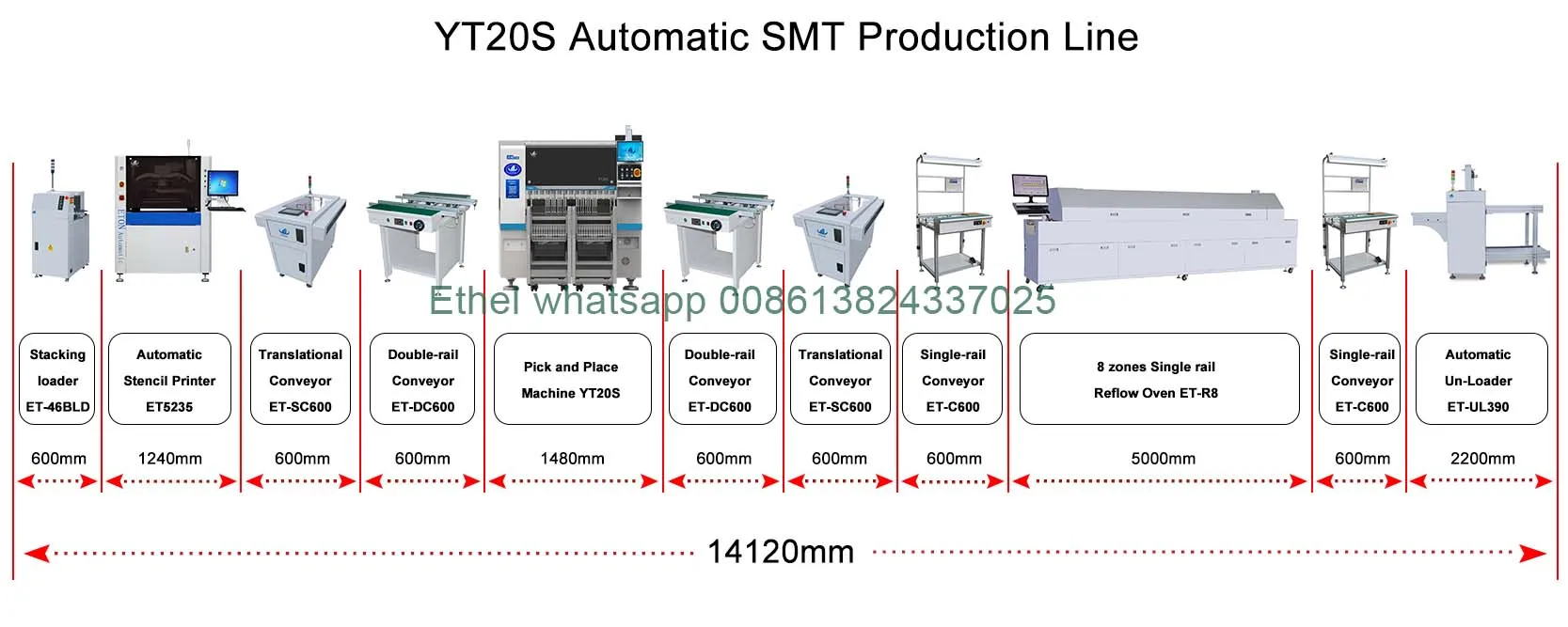

led smt display making machine smt production line equipment

- Category: >>>

- Supplier: Shenzhen Eton Automation Equipment Co. Ltd.

Share on (1601222489855):

Product Overview

Description

Product Description

MOUNTING SPEED, ACCURACY AND STABILITY

HIGH-SPEED MULTI INTEGRATED MACHINE, BREAKING THROUGH INDUSTRY CONVENTIONS, GREATLY IMPROVING

HIGH-SPEED MULTI INTEGRATED MACHINE, BREAKING THROUGH INDUSTRY CONVENTIONS, GREATLY IMPROVING

Four beam with FourTrack,Four mounting head mounting independently at the same time

Flexible PCB handling capabilities, multi -station, multi-material mounting

X,Y, and Z axis all adopt self-developed high-end magnetic linear motor

automatic nozzle change function(option)

world's first use of single-phase 220V power supply, low energy consumption

Each head is independently control by separately driver, each nozzle could be CPK testing independently

Apply to 0201~15*15mm tape reel package

Integrated placement head

An integrated head design,and 10 sets of z axis independently controlled by modular magnetic linear motor,resulting in significant improvements in speed,accuracy,stability

Precise Corner system

The modular corner system independently controls the angle of each component to ensure high precision placement ,there are 10 nozzles per head

double drive gantry structure

Y axis adopts double drive with high end magnetic linear motor.higher stability

Optional Function

Feeder Cart

One Feeder Cart accommodates 23 PCSfeeder stations, Depending on the productrequirements, with a one-touch changeovermethod to minimize changeovertime.

Intelligent Electric Feeder

Support YT series double head intelligent electric tape reel feeder, by optically correcting the feeding position of the component, it can achieve stable, accurate and high-speed feeding.

12PCS Nozzle exchange station

Specification

PCB length width | MAX:500x350mm(length can be customized) MIN:50x50mm |

Components | 0201 ~ 15x15mm packaging materials. Height:20mm |

Mounting speed | 200000 CPH (Under the best conditions for our company) |

Mounting precision | ±0.03mm(Repeat precision) |

No. Of feeders station | 104PCS(Double material feeder, can load 64 trays of material) |

Power | AC220 50Hz |

Air supply | 0.4-0.6Mpa (4-6Kgf/㎡) |

Vacuum detection | Independent vacuum detection of reclaiming material |

Dimension | L 2795 X W 1497 X H 1687 |

Total weight | 3400kg |

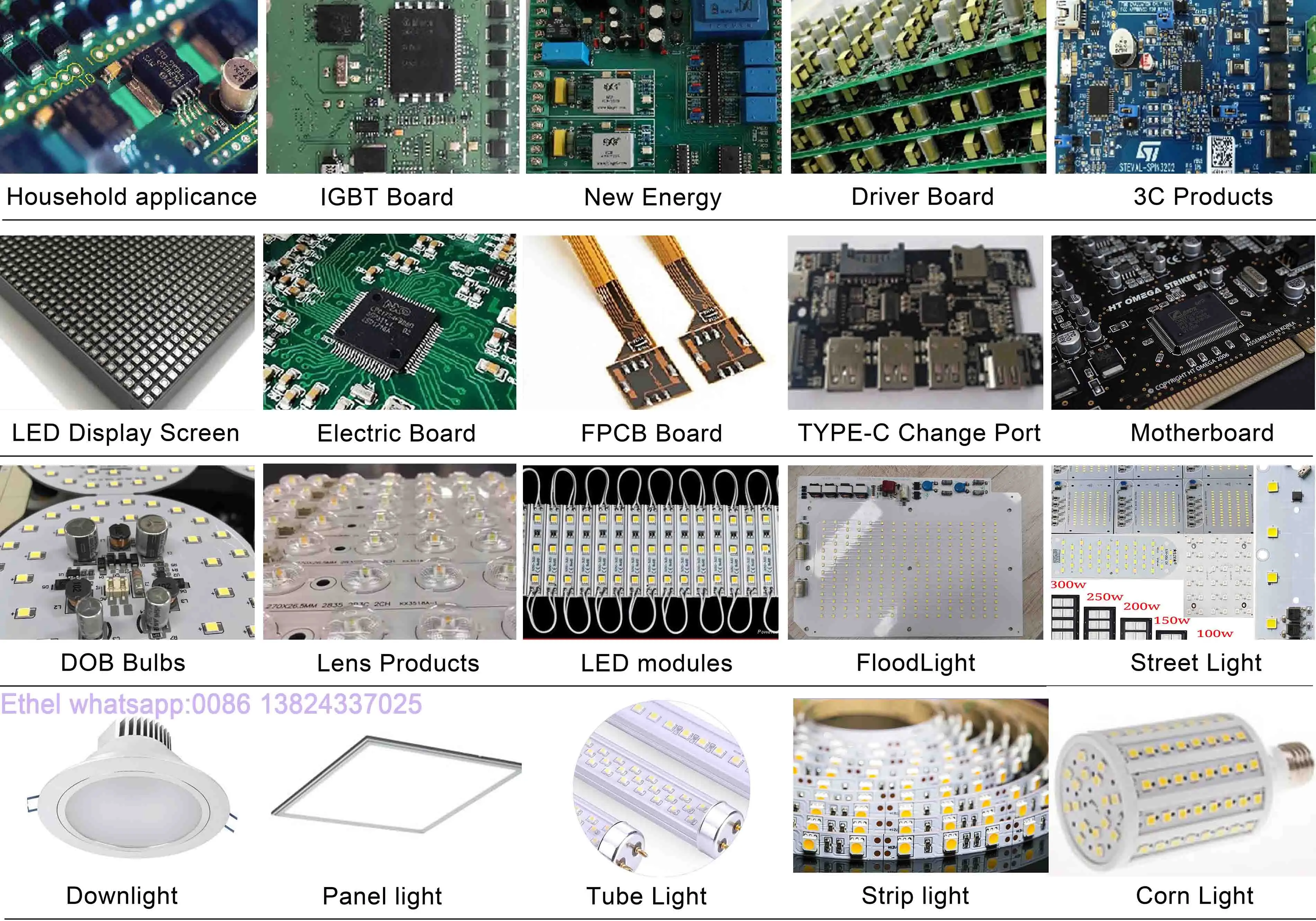

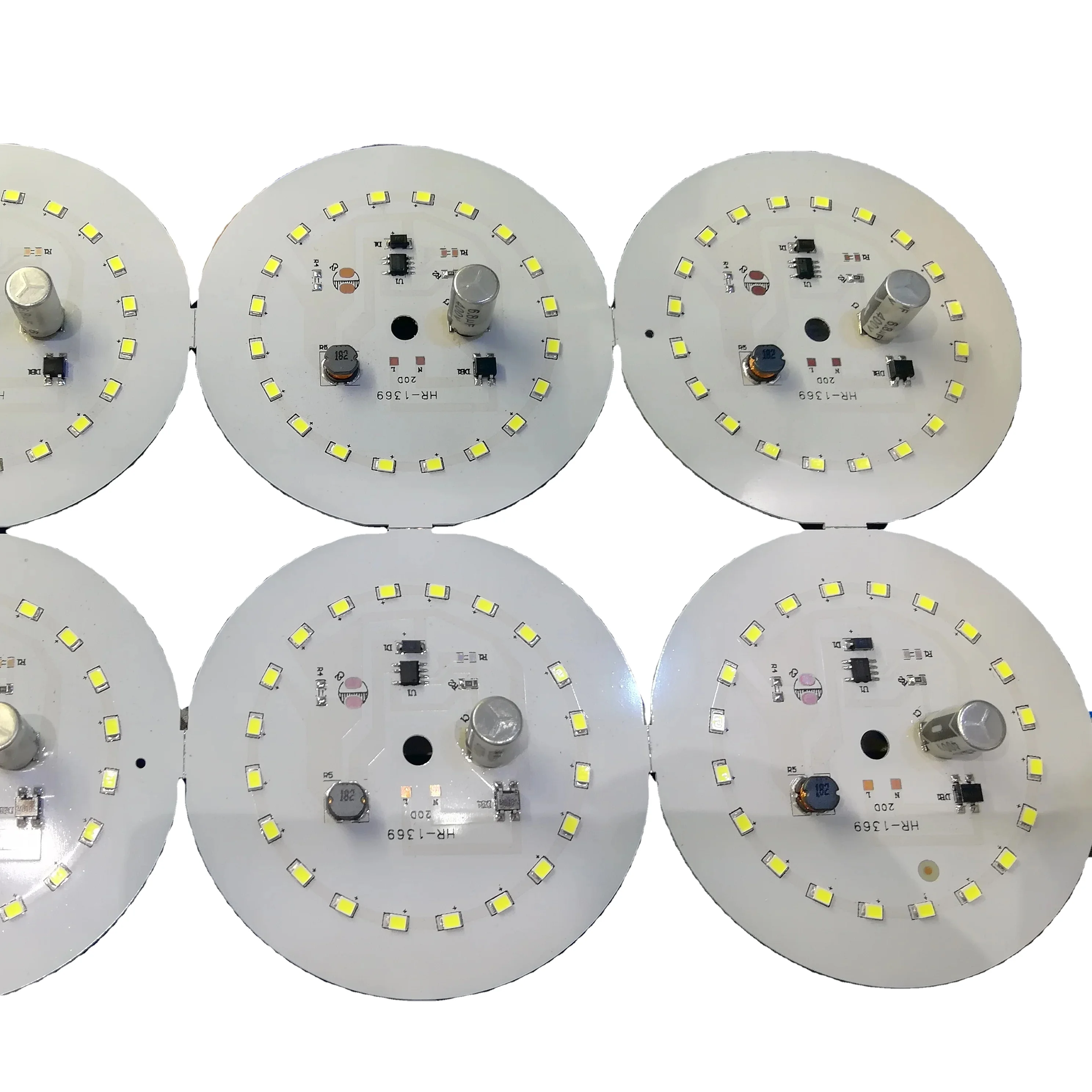

Application

suitable for high precision electric boards,power driver,SMT pcb,etc

Company Profile

ETON service

FREE installation and Training

We have overseas engineers who will go to your factory to help you with installation and training, so that you can smoothly produce and respond quickly

FULL SMT solution

We have professional engineers who will design suitable production line layout for you according to your products and factory area, and teach you how to set up SMT by hand

FAQ

Q1: How is the breakdown rate of machine?

A: Our machine is very stable, the breakdown rate is less than 0.001.

Q2: I have never used a placement machine before, is it easy to operate?

A: Machine is easy to operate, usually 3 to 5 days training of operating is enough.

Q3: What’s the MOQ?

A: One set machine, mini order is also welcomed.

Q4: Is your software interface in English?

A: English interface and Chinese interface are both available.

Q5: What’s the terms of payment? What about the trade term?

A: T/T is OK. You can choose FOB Shenzhen.

Q6:What is the difference between dual module and single module?

A:The dual module has one more module than the single module, which has more capacity and faster efficiency.

A: Our machine is very stable, the breakdown rate is less than 0.001.

Q2: I have never used a placement machine before, is it easy to operate?

A: Machine is easy to operate, usually 3 to 5 days training of operating is enough.

Q3: What’s the MOQ?

A: One set machine, mini order is also welcomed.

Q4: Is your software interface in English?

A: English interface and Chinese interface are both available.

Q5: What’s the terms of payment? What about the trade term?

A: T/T is OK. You can choose FOB Shenzhen.

Q6:What is the difference between dual module and single module?

A:The dual module has one more module than the single module, which has more capacity and faster efficiency.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices