Dual Rails Magazine Unloader Quality Assurance For SMT Production Line CE Certified With Customized Size

- Category: >>>

- Supplier: Shenzhen Censtar Technology Co. Ltd.

Share on (1601270973035):

Product Overview

Description

Description

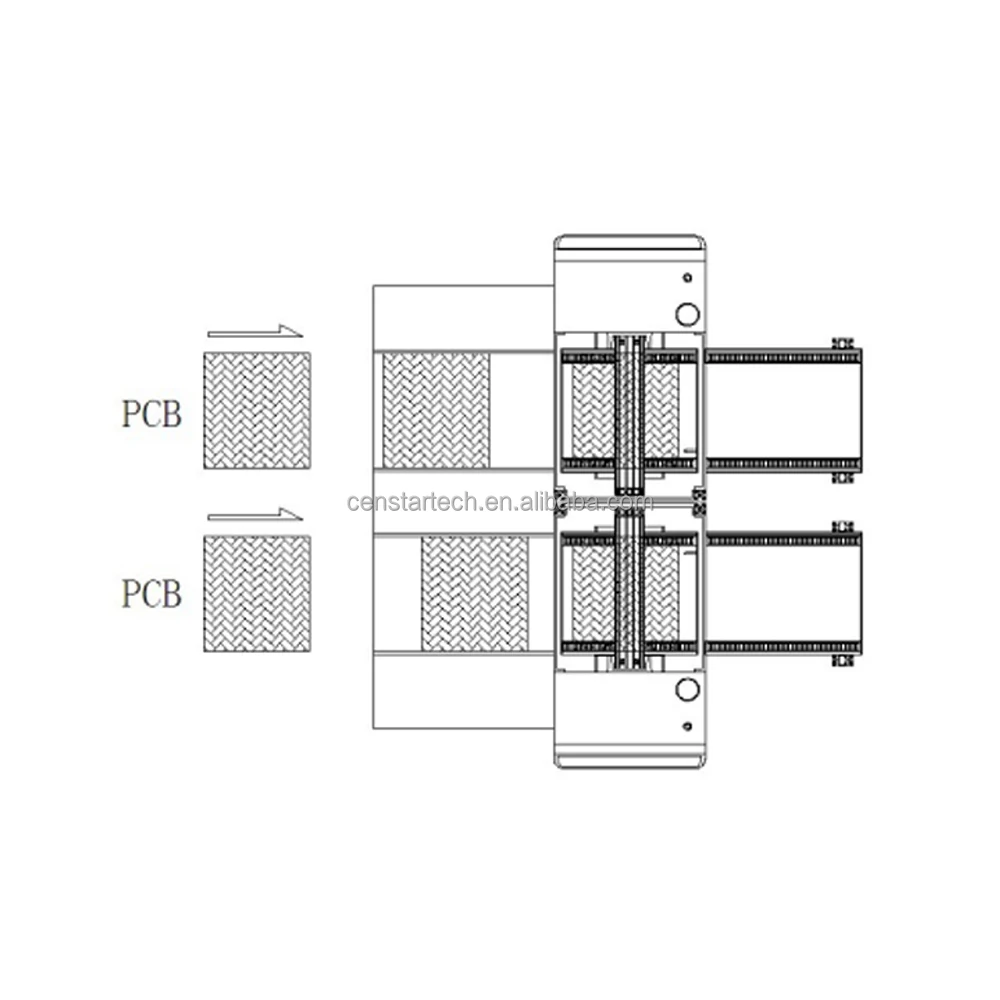

The unit provides automatic magazine change-over for continuous line unloading. PCB's are collected from an upstream pusher conveyor and pushed into the magazine. Full magazines are offloaded at an ergonomic low level.

Features

1. PLC+Screen touch panel control.

2. Magazine capacity: Top 2+Down 2.

3. Selectable pitch settings.

4. Dual lane high-speed unloader functions are selectable in the software.

5. Tower-light display for the machine’s working status.

6. Automatic magazine change-over.

7. Flexible platform to suit standard magazines.

8. Exchangeable magazine from the rear of the magazine.

9. Stepper motorized type pusher to enhance working stability.

10. Magazine infeed and outfeed are automatically driven by a motor on the platform.

11. SMEMA compatible.

2. Magazine capacity: Top 2+Down 2.

3. Selectable pitch settings.

4. Dual lane high-speed unloader functions are selectable in the software.

5. Tower-light display for the machine’s working status.

6. Automatic magazine change-over.

7. Flexible platform to suit standard magazines.

8. Exchangeable magazine from the rear of the magazine.

9. Stepper motorized type pusher to enhance working stability.

10. Magazine infeed and outfeed are automatically driven by a motor on the platform.

11. SMEMA compatible.

Technical Parameters | ||||||||

Model | BH-M-N | BH-L-N | BH-LL-N | BH-XL-N | ||||

Dimension | 1800*1435*1250mm | 2065*1690*1250mm | 2330*1810*1250mm | 2330*1950*1250mm | ||||

PCB size | 50*50-320*250mm | 50*50-445*330mm | 50*50-530*390mm | 50**50-530*460mm | ||||

Magazine size | 355*320*563mm | 460*400*563mm | 535*460*563mm | 535*530*563 | ||||

Transport height | 900±20mm | |||||||

Transfer direction | L-R or R-L | |||||||

Operation side | Front of the machine | |||||||

Fixed rail | 1&4 Rail | |||||||

Interface | SMEMA | |||||||

Conveyor belts | ESD flat belt | |||||||

Belt speed | 0.5-20m/min adjustable | |||||||

PCB edge support | 4mm | |||||||

PCB thickness | 0.6mm min | |||||||

Components clearance | 10mm below and above | |||||||

PCB weight | 2kg max | |||||||

PCB unloading time | Approx 6 seconds | |||||||

Magazine change-over time | Approx 30 seconds | |||||||

Pitch distance | 10.20.30.40mm pitch or specify | |||||||

Magazine capacity | Top 2+Down 2 | |||||||

Magazine weight | 60kg max | |||||||

Control | PLC | |||||||

Power supply | AC220V/110V, 50/60 HZ, 1 phase | |||||||

Power consumption | 300VA max. or specify | |||||||

Air supply | 4-6bar | |||||||

Air consumption | 10ltr/min max | |||||||

Weight | 320kg | 350kg | 380kg | 410kg | ||||

Packing Details: Plywood case, for export!

Port: Shenzhen

Delivery Details: About 10-15 working days.

Port: Shenzhen

Delivery Details: About 10-15 working days.

Our Company

Welcome to Shenzhen Censtar Technology Co., Ltd.

Founded with over 13 years of industry experience, Shenzhen Censtar Technology Co., Ltd. is a premier manufacturer of SMT & DIP handling machines, dedicated to serving the electronics industry. Based in Shenzhen, China, we operate our factory, allowing us to deliver high-quality, customized automation solutions to our global clients.

Our strong R&D background in automation drives our innovation, ensuring that our machines are built with the latest technology to ensure durability and high performance. We are committed to delivering quality products and customer satisfaction, serving clients in over 20 countries. Our experienced engineering team provides customized solutions, technical support, and comprehensive after-sales service to ensure your success.

Choose Shenzhen Censtar Technology for reliable, innovative, and advanced SMT & DIP handling solutions. Contact us to discover how we can contribute to your manufacturing success.

Our strong R&D background in automation drives our innovation, ensuring that our machines are built with the latest technology to ensure durability and high performance. We are committed to delivering quality products and customer satisfaction, serving clients in over 20 countries. Our experienced engineering team provides customized solutions, technical support, and comprehensive after-sales service to ensure your success.

Choose Shenzhen Censtar Technology for reliable, innovative, and advanced SMT & DIP handling solutions. Contact us to discover how we can contribute to your manufacturing success.

Q: What can we do for you?

A: We have more than 13 years of experience in designing and manufacturing SMT & DIP Assembly machines and PCB Handling Machines. PCB Conveyor, PCB Loader, PCB Unloader, PCB Buffer, Surface Cleaning Machines, PCB Shuttle Conveyor, Reflow Oven, Wave Soldering, Pick and Place, SPI, AOI and much more. We take pride in our ability to provide innovative solutions that meet the specific needs of our clients.

Q: Are you a trade company or manufacturer?

Q: What is your delivery date?

A: The delivery date is about 10-15 working days after receive the payment.

Q: What is your payment terms?

A: 30% deposit before production, 70% payment before shipment.

Q: What is the payment way?

A: We accept the payment terms: T/T, Western Union, etc.

Q: Is this machine easy to use? If I have no experience, can I operate it well?

A: Yes, Our machine is easy to use. Usually, you need 1 day to learn how to operate. If you are a technician, learning will be faster. If you still have questions, please contact us.

Q: Do you provide user manuals and operating videos to support us?

A: We will provide an English user manual for free, and provide an operation video. Our software is all in English.

Q: If we come to your factory, will you provide free training?

A: Yes, of course. You are warmly welcome to visit our factory and we will arrange free training for you.

Q: When we encounter problems during operation, what services can you provide?

A: We can invite our engineers to your company for guidance, but you are responsible for the engineer's round-trip flight tickets, food, and accommodation.

Q: How can we guarantee quality?

A: Strict QC before shipping the products, Always final Inspection before shipment.

Q: Why choose you?

A: We are the Leading SMT & DIP Machine Manufacturer in China. We provide you with high-quality materials at factory prices. OEM & ODM services offered, meet all your needs. We ensure One-Stop after-sales service.

Thank you for your time and consideration. We look forward to the possibility of establishing a successful business partnership with you.

A: We have more than 13 years of experience in designing and manufacturing SMT & DIP Assembly machines and PCB Handling Machines. PCB Conveyor, PCB Loader, PCB Unloader, PCB Buffer, Surface Cleaning Machines, PCB Shuttle Conveyor, Reflow Oven, Wave Soldering, Pick and Place, SPI, AOI and much more. We take pride in our ability to provide innovative solutions that meet the specific needs of our clients.

Q: Are you a trade company or manufacturer?

A: We are a manufacturing company, located in Shenzhen, China. Full SMT & DIP machines manufacturer; OEM & ODM service are available.

Q: What is your delivery date?

A: The delivery date is about 10-15 working days after receive the payment.

Q: What is your payment terms?

A: 30% deposit before production, 70% payment before shipment.

Q: What is the payment way?

A: We accept the payment terms: T/T, Western Union, etc.

Q: Is this machine easy to use? If I have no experience, can I operate it well?

A: Yes, Our machine is easy to use. Usually, you need 1 day to learn how to operate. If you are a technician, learning will be faster. If you still have questions, please contact us.

Q: Do you provide user manuals and operating videos to support us?

A: We will provide an English user manual for free, and provide an operation video. Our software is all in English.

Q: If we come to your factory, will you provide free training?

A: Yes, of course. You are warmly welcome to visit our factory and we will arrange free training for you.

Q: When we encounter problems during operation, what services can you provide?

A: We can invite our engineers to your company for guidance, but you are responsible for the engineer's round-trip flight tickets, food, and accommodation.

Q: How can we guarantee quality?

A: Strict QC before shipping the products, Always final Inspection before shipment.

Q: Why choose you?

A: We are the Leading SMT & DIP Machine Manufacturer in China. We provide you with high-quality materials at factory prices. OEM & ODM services offered, meet all your needs. We ensure One-Stop after-sales service.

Thank you for your time and consideration. We look forward to the possibility of establishing a successful business partnership with you.

Contact information

Sammy Arefin

Shenzhen Censtar Technology Co., Ltd.

Cell/Whatsapp: +86 15638536680

E-mail/Skype: sammy@censtartech.com

LinkedIn: https://www.linkedin.com/in/sammy-arefin/E-mail/Skype: sammy@censtartech.com

We Recommend

New Arrivals

New products from manufacturers at wholesale prices