NeoDen SMT Automatic Online Spi Machine Solder Paste Inspection Machine

- Category: >>>

- Supplier: Zhejiang Neoden Technology Co. Ltd.Zhejiang Ltd.

Share on (1601341651318):

Product Overview

Description

Product Description

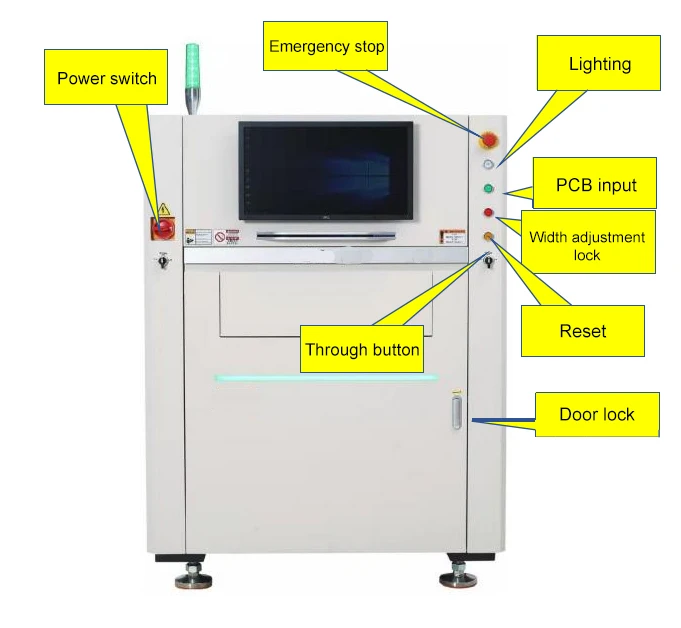

NDS1 Solder Paste Inspection machine(SPI)-NeoDen Check Solder Paste Cover Performance from Stencil Printer SMT Automatic Online Solder Paste Inspection Machine SPI NDS1

NDS1 is used to detect and monitor the quality of solder paste printing. With the increasing precision of electronic products, chip components are becoming smaller and smaller, and the requirements for solder paste printing quality are gradually increasing, NDS1 can Effectively guarantee the printing quality, improve the printing quality, reduce the defect rate of the product, save labor, and improve the production efficiency.

Spotlights

* The all-digital high-speed CCD camera cooperates with the industrial telecentric lens, high resolution, ultra wide depth offield, ultra low distortion and unique parallel light design, etc. It can clearly image the circuit board.

*Realize shadowless 3D detection without worrying about inaccurate measurement caused by shadows; five-step phase shift algorithm based on defocused sine grating stripes, height detection accuracy upto 1 pm

*The AC servo motor system, coupled with precision ball screws and linear guide pairs, ensures high-speed and accurate detection capabilities」fast and stable movement, and positioning accuracy of less than 10 卩 m.

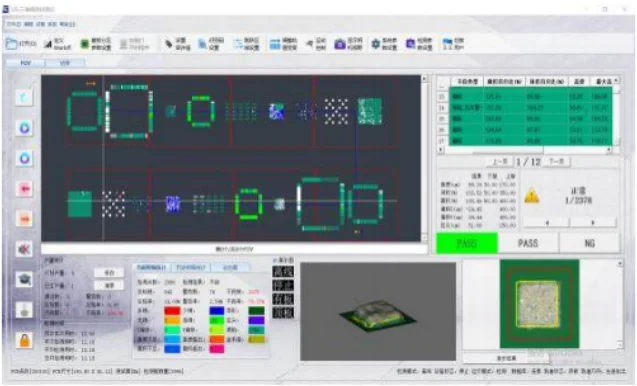

*Display histogram/control chart and true-color three-dimensional stereoscopic image, and export reports and pictures at any time period to trace the root cause of badness from the detection results

*ReaHime measurement and compensation of board bending (refer to ideal board), can reach less than 2mm; provide clear PCB images and measurement data online in real time

*Support Gerber, CAD import, support offline programming and manual programming, easy to operate, can switch between Chinese and English system;

*Through more intuitive software, display 2D/3D true color images to help users read bad; choose 2 commonly used Mark points.

*Realize shadowless 3D detection without worrying about inaccurate measurement caused by shadows; five-step phase shift algorithm based on defocused sine grating stripes, height detection accuracy upto 1 pm

*The AC servo motor system, coupled with precision ball screws and linear guide pairs, ensures high-speed and accurate detection capabilities」fast and stable movement, and positioning accuracy of less than 10 卩 m.

*Display histogram/control chart and true-color three-dimensional stereoscopic image, and export reports and pictures at any time period to trace the root cause of badness from the detection results

*ReaHime measurement and compensation of board bending (refer to ideal board), can reach less than 2mm; provide clear PCB images and measurement data online in real time

*Support Gerber, CAD import, support offline programming and manual programming, easy to operate, can switch between Chinese and English system;

*Through more intuitive software, display 2D/3D true color images to help users read bad; choose 2 commonly used Mark points.

Specification

Model | NDS1 | ||

Check System1 | Camera | 5 mega-pixel | |

Lighting system | Surrounded RGB | ||

FOV | 48mm*40mm(20 μm) | ||

Processing time per frame | Less than 7S | ||

Check content | area,volume,height,shape,offset, continuous tin electrodeposit | ||

Check System2 | Shortage types | Tin statues(less, more,offset,out of line,height) | |

Max test height | 400 μm | ||

Solder scope | 0.2mm*0.2mm~12mm*12mm | ||

Height detection precision | 1 μm | ||

Repeatedly(volume,area,height) | less than 1 μm@3sigma | ||

Repeatedly and reproducibilty | less than 10% | ||

Software system1: | Operation system | Windows 7 Ultimate 64bit | |

1)Idetification system: | 768*768~1536*1536 | ||

Feature | 3d raster camera(double is optional) | ||

Interface | 2D AND and 3D truecolor image | ||

MARK | Can choose 2 commom mark point | ||

2)Programe: | Support gerber,CAD input,offline and manual program | ||

Software system2: | Offline SPC: | Support | |

SPC Report: | Anytime Report | ||

Control Graphic: | Volume, area, height, offset | ||

Export content: | Excel, image(jpg,bmp) | ||

Mechanical-1 | 1)Pcb transfer system: | 900±30mm, substrate fixing mode:edge lock plate,automatic board in and out and adjustment system, match SMEMA | |

2)Min&Max pcb size: | 50mm×50mm-500mm×460mm | ||

3)PCB thickness: | 0.6mm~6mm | ||

4)Plate edge clearance | up: 3mm down: 3mm | ||

5)Transfer speed: | 1500mm/s(MAX) | ||

Mechanical-2 | 6)Plate bending compensation: | less than 2mm | |

Driver equipment: AC servo motor system | |||

Setting accuracy:less than 1 μm | |||

Moving speed: 600mm/s | |||

Control system | 1)Host: | Industry control PC, intel 6 core cpu,16GDDR,1T | |

2)Displayer: | 22 inch lcd widescreen display | ||

Other parameters | 1)External sizes: | L (1090mm) ×W (1290mm)×H (1534mm). Not including light,keypad,display | |

2) Machine weight: | 750kg | ||

3)Power requres: | AC220V±10%,50/60HZ,1.8kVA | ||

4)Compressed air requirement: | 4~6Kg/cm² | ||

5)Environment temperature: | 10~40℃ | ||

6)Relative humidity: | 30-80%RH | ||

Features

High speed can achieve maximum throughput

The all-digital high-speed CCD camera cooperates with the industrial telecentric lens, high resolution, ultra wide depth offield, ultra low distortion and unique parallel light design, etc. It can clearly image the circuit board.

3D raster projection head

Realize shadowless 3D detection without worrying about inaccurate measurement caused by shadows; five-step phase shift algorithm based on defocused sine grating stripes, height detection accuracy upto 1 pm

High precision mechanical platform

The AC servo motor system, coupled with precision ball screws and linear guide pairs, ensures high-speed and accurate detection capabilities」fast and stable movement, and positioning accuracy of less than 10 卩 m.

Supports Offline SPC

Display histogram/control chart and true-color three-dimensional stereoscopic image, and export reports and pictures at any time period to trace the root cause of badness from the detection results

PCB Plate Bending compensation solution

ReaHime measurement and compensation of board bending (refer to ideal board), can reach less than 2mm; provide clear PCB images and measurement data online in real time

Friendly Interface

Support Gerber, CAD import, support offline programming and manual programming, easy to operate, can switch between Chinese and English system;

Through more intuitive software, display 2D/3D true color images to help users read bad; choose 2 commonly used Mark points.

Through more intuitive software, display 2D/3D true color images to help users read bad; choose 2 commonly used Mark points.

SMT Line

Related Products

About Us

「About NEODEN」

Zhejiang NeoDen Technology Co., Ltd. has been manufacturing and exporting various small pick and place machines since 2010. Taking advantage of our own rich experienced R&D, well trained production, NeoDen wins great reputation from the world wide customers.

With global presence in over 130 countries, the excellent performance, high accuracy and reliability of NeoDen PNP machines make them perfect for R&D, professional prototyping and small to medium batch production. We provide professional solution of one-stop SMT equipment.

In our global Ecosystem, we collaborate with our best partners to deliver a more closing sales service, high professional and efficient technical support.

We believe that great people and partners make NeoDen a great company and that our commitment to Innovation, Diversity and Sustainability ensures that SMT automation is accessible to every hobbyist everywhere.

Payment & Shipping

FAQ

Q1: Do you provide software updates?

For customers who buy our machine, we can offer free upgraded software for you.

Q2: Does our machine need air supply?

We have vacuum pumps inside the machine, it does not need air supply.

Q3: This is the first time I use this kind of machine, is it easy to operate?

We have English user manual and guide video to teach you how to use the machine. If you still have question, pls contact us by email/skype/phone etc for online service.

Q4: How about the warranty?

We have 2 years warranty for YY1,NeoDen4, K1830, NeoDen9, In6, IN12C,ND1,ND2,NDS1 and 1 year for all other models with lifetime after-sale support.

Q5: How can I buy machine from you?

(1) Consult us on line or by e-mail;

(2) Negotiate and confirm the final price, shipping, payment method and other terms;

(3) Send you the proforma invoice and confirm your order;

(4) Make the payment according to the method put on proforma invoice;

(5) We prepare your order in terms of the proforma invoice after confirming your full payment . And 100% quality check before shipping;

(6) Send your order via express or by air or by sea.

For customers who buy our machine, we can offer free upgraded software for you.

Q2: Does our machine need air supply?

We have vacuum pumps inside the machine, it does not need air supply.

Q3: This is the first time I use this kind of machine, is it easy to operate?

We have English user manual and guide video to teach you how to use the machine. If you still have question, pls contact us by email/skype/phone etc for online service.

Q4: How about the warranty?

We have 2 years warranty for YY1,NeoDen4, K1830, NeoDen9, In6, IN12C,ND1,ND2,NDS1 and 1 year for all other models with lifetime after-sale support.

Q5: How can I buy machine from you?

(1) Consult us on line or by e-mail;

(2) Negotiate and confirm the final price, shipping, payment method and other terms;

(3) Send you the proforma invoice and confirm your order;

(4) Make the payment according to the method put on proforma invoice;

(5) We prepare your order in terms of the proforma invoice after confirming your full payment . And 100% quality check before shipping;

(6) Send your order via express or by air or by sea.

If you have any questions, welcome to contact us!

We Recommend

New Arrivals

New products from manufacturers at wholesale prices