CF 1LQF Aluminium&Titanium Alloy Banbury Mixer Machine for MIM

- Category: Chemical Machinery & Equipment >>>

- Supplier: Dongguan C Fine Machinery Technology Co. Ltd.

Share on (60583040438):

Product Overview

Description

Picture of our company

Dongguan Cfine Machinery Technology Co.,Ltd. is a professional feedstock mixing and granulating equipment manufacturer that specializes in making Banbury mixer and pellets granulating extrusion machine .

Our high-quality products have gained international recognition and acceptance not only by worldwide rubber market, even also for Industries like Electrical, Ceramic,Metal Industries etc...and also have been exported to global customers including USA,Korea,Kazakhstan ,India,Malaysia,England and many European Countries.

Over the past decade our products have rapidly built a reputation for Honesty and Reliability.

The Company has strongly believe that producing excellent quality products is the best method of Advertising. Even more by understanding more about our customers and the industry, we are able to improve our products in all aspects, whilst attempting to achieve International Accreditation.

You are welcome to visit our company and test the formula,make sample in our independent laboratory.

Our Team

We aim to provide Total Customer Satisfaction in terms of Quality, On-Time Delivery, Competitive Costing and yet with First Class Services that Meet and Exceed customer requirements.

Workshop

Our Manufacturing experience and Modern Technology has given us the edge in delivering high quality service to all our customers.

Applications:

Open-Close Type Atmosphere Protection Kneader(1LKH) is suitable for mixing

sticky and hard metal&ceramic powder,titanium/aluminium alloy powder.

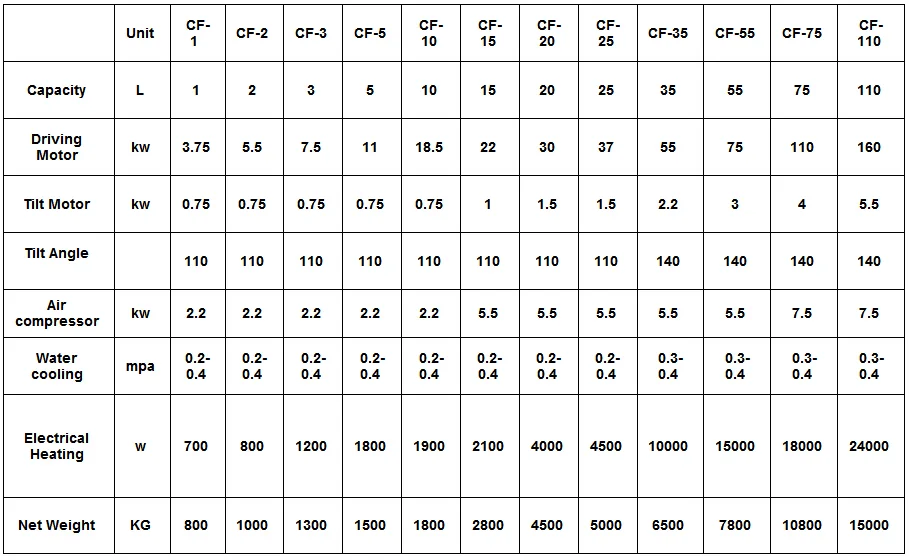

Main Technical Specifications

Working principle :

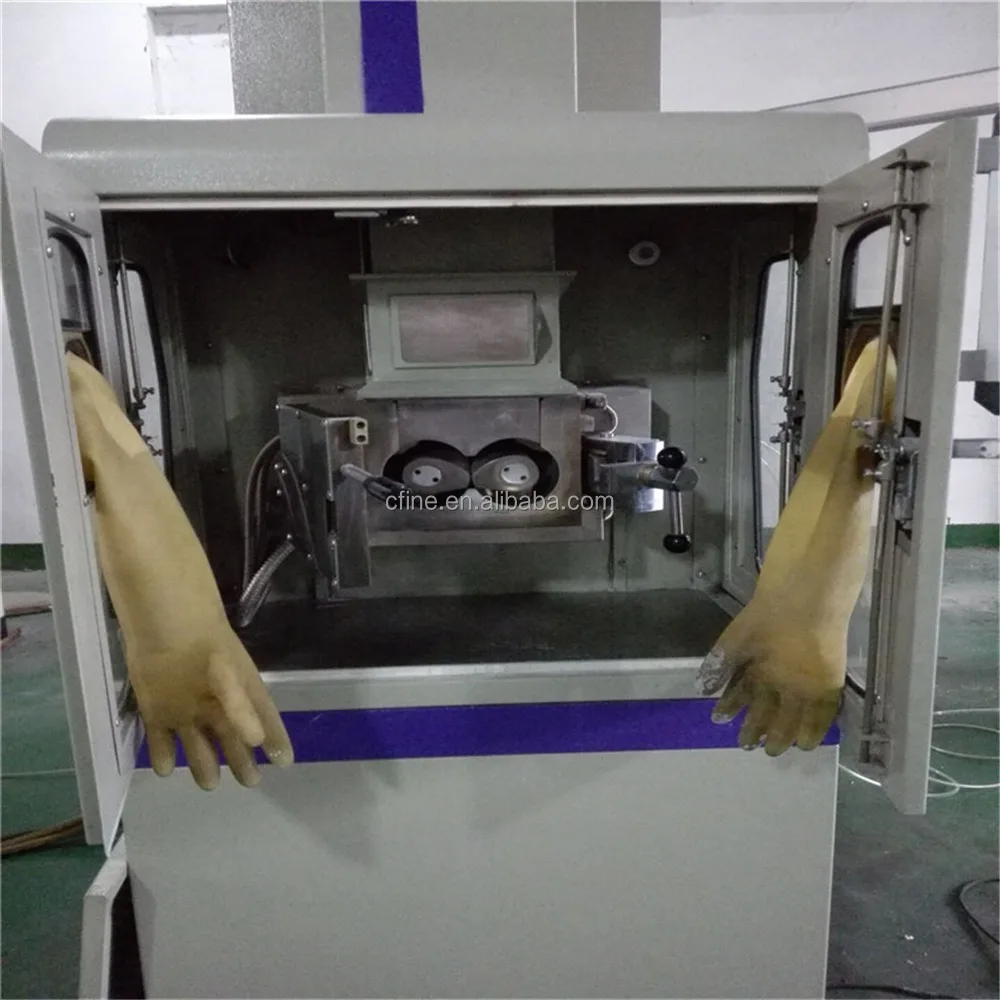

Equipped with advanced coaxial separation technology, to end faces of the rotor axis can be separated, breaking the bottleneck of traditional mixer, Changfeng open type

gas protection mixer for expensive, high hardness, easy pollution and difficult to clean in terms of design. The whole imported special alloy materials with special heat treatment to achieve super abrasive hardness polishing and surface treatment, unnecessary economic losses caused by pollution control material effectively. The practice of opening and closing of the room at the same time, the rotor suspended in, the staff can clean up to any one area, no dead round design.

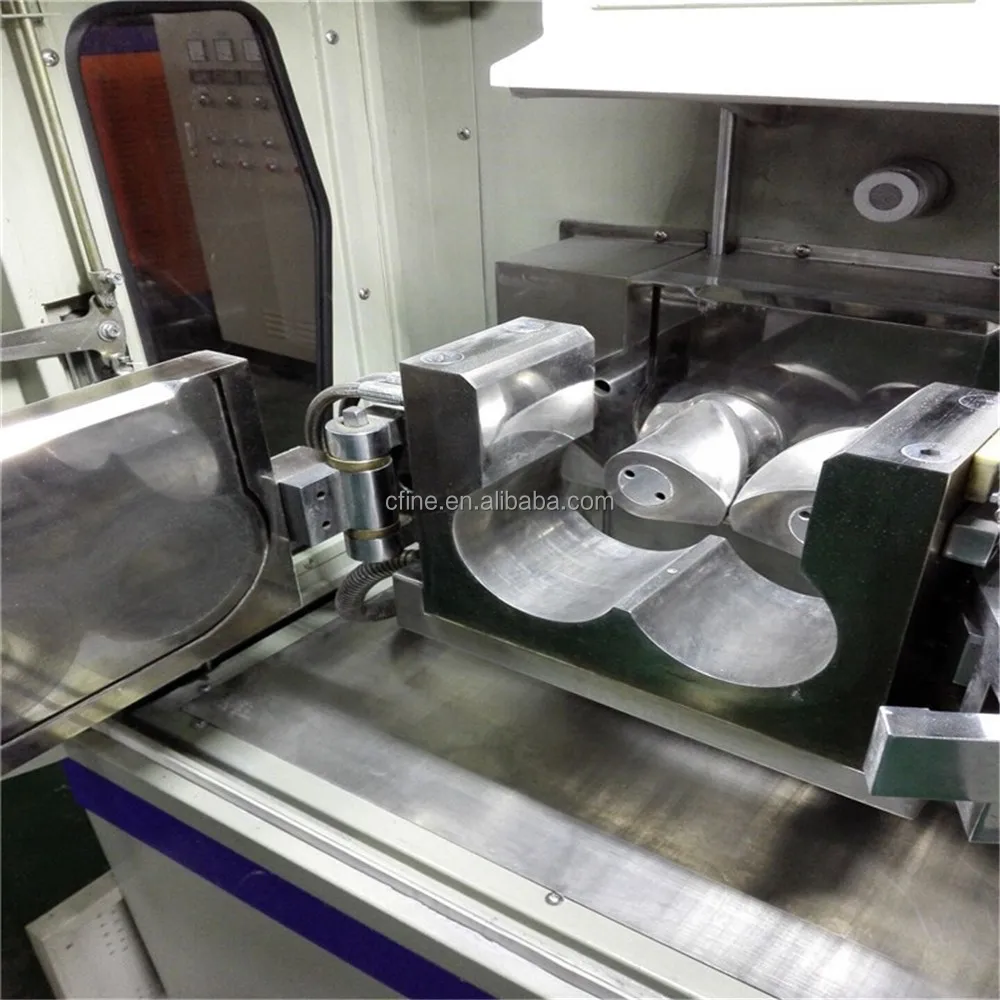

Mixing chamber:

The mixing chamber is "W" shaped and uses an "M" shaped compression cap to form a fully enclosed mixing system. The mixing chamber is made of high-carbon steel, tempered and vacuum-treated for 72 hours, and the surface is hard chrome-plated to increase the hardness, ensuring that the chamber is hard and wear-resistant.The mixing chamber can be turned over 110 degrees, and the mixing shaft has the functions of forward rotation and reverse rotation, which makes the discharge more convenient and quick.

CHINA INTERNATIONAL OPTOELECTRONIC

EXPO.

CHINAPLAS2018.

Year 2018 in Shanghai.

Rubber-plas Malaysia 2016.

Year 2016 in Kuala Lumpur.

The18th CIOE .

Year 2016 in Shenzhen.

The 29th CHINAPLAS.

Year 2015 in Guangzhou.

CE Certificate

ISO 9001:2015

Patent

Shipping.

Within 30 days after the deposit.

Packaging.

According to your requirements

Jack He Foreign Trade Sales

CFine Machinery Technology Co,. Ltd.

Tel:+86-769-81523338

Mob:+86-13829294617

Fax:+86-769-85905235

Wechat #:13829294617

Whatsapp:+8613829294617

Web://www.cfinemachinery.com/

Head Office:Shatang Village Jingmeng District Houjie town Dongguan City Guangdong China

We Recommend

New Arrivals

New products from manufacturers at wholesale prices