4500g 4800g Geosynthetic Clay Liner landfill and basement lining waterproofing solution GCL liners for landfills

- Category: >>>

- Supplier: Haoyang International Trade (shandong) Co. Ltd.Haoyang Ltd.

Share on (1601283903790):

Product Overview

Description

Product Description

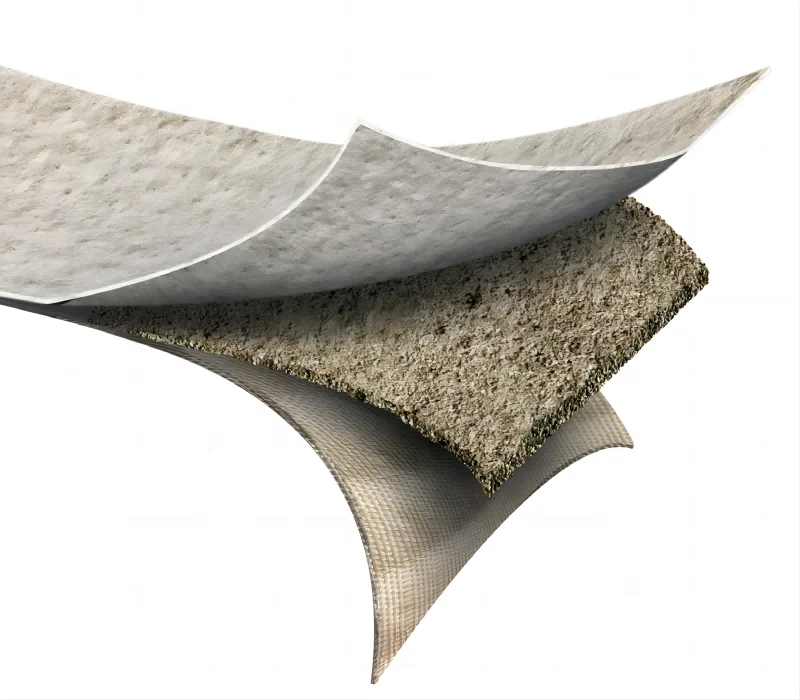

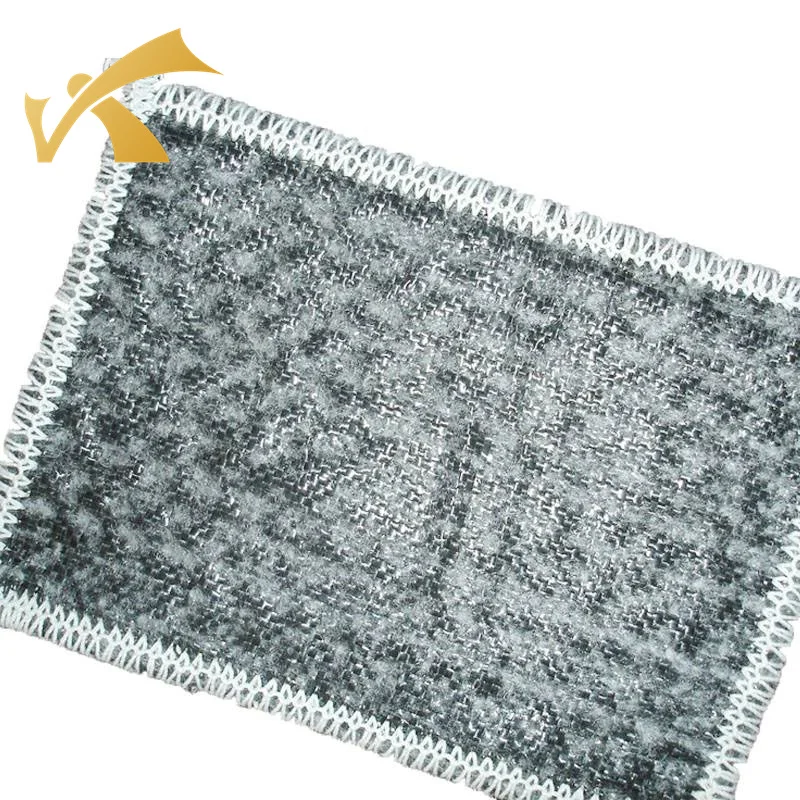

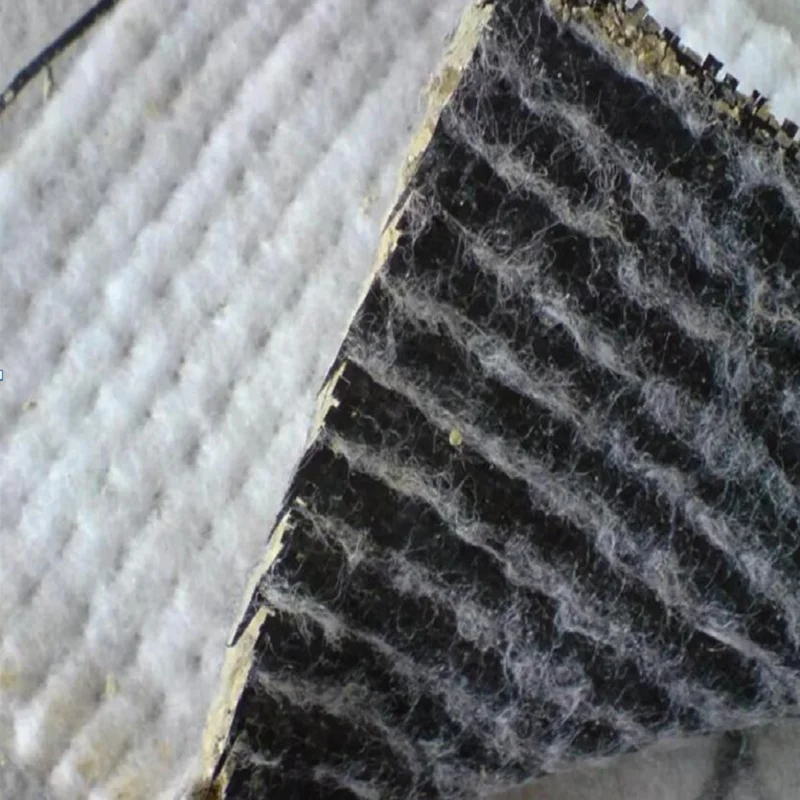

Geosynthetic Clay Liner (GCL), also known as a sodium bentonite composite waterproof pad, is designed by filling high-swelling sodium bentonite between special composite geotextile and non-woven fabric. The impermeable cushion, created using an acupuncture method, forms numerous small fiber spaces, preventing the flow of bentonite particles in one direction. When exposed to water, it creates a uniformly high-density colloidal waterproof layer within the pad, effectively preventing water leakage. GCL finds application in various areas, including artificial lakes, landfills, underground garages, roof gardens, pools, oil depots, and chemical yards.

Specification

item | Technical Indicator | ||||

GCL-NP | GCL-OF | GCL-AH | |||

Weight per unit area(g/m2) | ≥4000g/m2 | ||||

Bentonie swell index(ml/2g) | ≥24 | ||||

Ethylene blue absorption(g/100g) | ≥30 | ||||

Tensile strength (N/100mm) | ≥600 | ≥700 | ≥600 | ||

Racking strength(N/100mm) (for nonwovwn and woven fabric) | ≥40 | ≥40 | - | ||

Racking strength(N/100mm) (for HDPE films and nonwoven fabric) | - | ≥30 | - | ||

Permeability(m/s) | ≤5.0x10-11 | ≤5.0x10-12 | ≤1.0×10-12 | ||

Anti-static water pressure | 0.4Mpa,1h, not seepage | 0.6Mpa,1h,not seepage | |||

Filtration loss (ml) | ≤18 | ≤18 | ≤18 | ||

Bentonite durability (ml/2g) | ≥20 | ≥20 | |||

Performance features

1, Impermeability: GCLs provide excellent impermeability due to the swelling nature of sodium bentonite, forming a tight waterproof barrier when in contact with water.

2, Sealing Capability: The ability of GCLs to swell and form a colloidal waterproof layer enhances their sealing capability, preventing water from permeating through the liner.

3, Flexibility: GCLs are flexible and conform to the contours of the underlying surface, making them suitable for different shapes and profiles in various construction projects.

4, Chemical Resistance: GCLs exhibit resistance to a wide range of chemicals, making them suitable for applications in environments with different types of contaminants.

5, Ease of Installation: The installation process of GCLs is relatively simple compared to traditional clay liners. This can result in cost savings and faster project completion.

2, Sealing Capability: The ability of GCLs to swell and form a colloidal waterproof layer enhances their sealing capability, preventing water from permeating through the liner.

3, Flexibility: GCLs are flexible and conform to the contours of the underlying surface, making them suitable for different shapes and profiles in various construction projects.

4, Chemical Resistance: GCLs exhibit resistance to a wide range of chemicals, making them suitable for applications in environments with different types of contaminants.

5, Ease of Installation: The installation process of GCLs is relatively simple compared to traditional clay liners. This can result in cost savings and faster project completion.

Applications

Geosynthetic Clay Liners (GCLs) find applications in various engineering and environmental protection projects due to their impermeable and sealing properties. Here are some common applications of GCLs:

1, Landfills: GCLs are widely used as bottom liners and caps in landfills to prevent the leaching of contaminants into the soil and groundwater. They contribute to the environmental protection and containment of waste materials.

2, Artificial Lakes and Ponds: GCLs are used to line the bottoms and sides of artificial lakes and ponds, providing a waterproof barrier that helps retain water and prevent seepage.

3, Water Containment and Reservoirs: GCLs are employed in the construction of water containment structures, such as reservoirs and dams, to create impermeable barriers that prevent water from escaping.

4, Mining Applications: GCLs are used in mining operations to line tailings ponds and storage facilities, preventing the release of potentially harmful substances into the surrounding environment.

5, Oil and Gas Industry: GCLs are applied in the construction of containment structures for oil depots, chemical storage yards, and other facilities in the oil and gas industry to prevent leakage of hazardous substances.

6, Wastewater Treatment: GCLs can be employed in wastewater treatment facilities to line lagoons and containment structures, preventing the seepage of treated or untreated wastewater into the surrounding soil.

The versatility and effectiveness of GCLs make them valuable in a wide range of applications where impermeability and containment are critical considerations. The specific application depends on the project requirements and the environmental conditions of the site.

1, Landfills: GCLs are widely used as bottom liners and caps in landfills to prevent the leaching of contaminants into the soil and groundwater. They contribute to the environmental protection and containment of waste materials.

2, Artificial Lakes and Ponds: GCLs are used to line the bottoms and sides of artificial lakes and ponds, providing a waterproof barrier that helps retain water and prevent seepage.

3, Water Containment and Reservoirs: GCLs are employed in the construction of water containment structures, such as reservoirs and dams, to create impermeable barriers that prevent water from escaping.

4, Mining Applications: GCLs are used in mining operations to line tailings ponds and storage facilities, preventing the release of potentially harmful substances into the surrounding environment.

5, Oil and Gas Industry: GCLs are applied in the construction of containment structures for oil depots, chemical storage yards, and other facilities in the oil and gas industry to prevent leakage of hazardous substances.

6, Wastewater Treatment: GCLs can be employed in wastewater treatment facilities to line lagoons and containment structures, preventing the seepage of treated or untreated wastewater into the surrounding soil.

The versatility and effectiveness of GCLs make them valuable in a wide range of applications where impermeability and containment are critical considerations. The specific application depends on the project requirements and the environmental conditions of the site.

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Company Profile

Haoyang Environmental Co., Ltd. (Haoyang), established in June 2008, is located in the National High-Tech Industrial Development Zone of Yucheng, Dezhou, Shandong Province, China. The company is a high-tech comprehensive service provider that specializes in the research, development, and manufacturing of geosynthetic materials, environmental engineering consulting, design, construction, soil remediation, environmental management, and comprehensive treatment and disposal of solid waste.

Haoyang has obtained certifications for ISO 9001 Quality Management System, ISO 14001 Environmental Management System, OHSAS 18001 Occupational Health and Safety Management System, as well as CQC Environmental Product Certification. The company has also received national laboratory accreditation and has been recognized as a "Shandong Province Enterprise Technology Center" and a "New Environmental Protection Material Engineering Laboratory."

With a professional technical research and development team, Haoyang focuses on environmental engineering design and consulting, research and development of environmental engineering materials, as well as the research, development, and application of technologies for environmental pollution control and hazardous waste treatment and disposal. The company holds three invention patents, thirty-two utility model patents, and has received two provincial level scientific and technological achievements certifications

Haoyang is committed to becoming an international comprehensive service provider in environmental protection technology, making positive contributions to the development and application of environmental protection technology.

Haoyang has obtained certifications for ISO 9001 Quality Management System, ISO 14001 Environmental Management System, OHSAS 18001 Occupational Health and Safety Management System, as well as CQC Environmental Product Certification. The company has also received national laboratory accreditation and has been recognized as a "Shandong Province Enterprise Technology Center" and a "New Environmental Protection Material Engineering Laboratory."

With a professional technical research and development team, Haoyang focuses on environmental engineering design and consulting, research and development of environmental engineering materials, as well as the research, development, and application of technologies for environmental pollution control and hazardous waste treatment and disposal. The company holds three invention patents, thirty-two utility model patents, and has received two provincial level scientific and technological achievements certifications

Haoyang is committed to becoming an international comprehensive service provider in environmental protection technology, making positive contributions to the development and application of environmental protection technology.

Our Advantages

1, We are a factorty with more than 15 years experience.Our factory Covers an area of over 230 acres, with more than 40,000 square meters of standardized industrial workshops, equipped with over 26 modern production lines for geosynthetic materials, the facility boasts a total annual production capacity of 93,500 tons.

2, Abtained ISO 9001 Quality Management System, ISO 14001 Environmental Management System, OHSAS 18001 Occupational Health and Safety Management System, as well as CQC Environmental Product Certification.

3, Professional teamWe boast a dedicated team of professionals committed to excellence. Our skilled and passionate individuals collaborate seamlessly, bringing expertise from diverse backgrounds. Together, we form a powerhouse that tackles challenges with innovation and precision. Our team's proficiency, coupled with a shared commitment to delivering top-notch results, ensures success in every endeavor. We take pride in our collective strength and the impact we make as a unified, professional team.

If you have any need or question just feel free to contact Echo, I will always at your service:

Phone/WhatsApp/ WeChat : +86166157730827 Email: export@hygeosynthetics.com

FAQ

1. who are we?

We are based in Shandong, China, start from 2023,sell to Southeast Asia(30.00%),Africa(15.00%),North America(10.00%),Oceania(10.00%),Mid East(10.00%),Western Europe(10.00%),Eastern Europe(5.00%),Eastern Asia(5.00%). There are total about 301-500 people in our office.

We are based in Shandong, China, start from 2023,sell to Southeast Asia(30.00%),Africa(15.00%),North America(10.00%),Oceania(10.00%),Mid East(10.00%),Western Europe(10.00%),Eastern Europe(5.00%),Eastern Asia(5.00%). There are total about 301-500 people in our office.

2, Are you a factory or trading company?

We are a professional manufacturer that specialized in geomembrane, geotextile, composite geomembrane etc with ISO9001 certificate more than 15 years.

We are a professional manufacturer that specialized in geomembrane, geotextile, composite geomembrane etc with ISO9001 certificate more than 15 years.

3, Could you send the sample before order confirmation?

Yes, we'd love to send a free sample to you for an evaluation if you need.

Yes, we'd love to send a free sample to you for an evaluation if you need.

4, How about the delivery time?

General within 3-7 days after received the deposit.

General within 3-7 days after received the deposit.

5, Can you produce the product according to customers' requirements?

Sure, we are professional manufacturer, OEM and ODM are both welcome.

Sure, we are professional manufacturer, OEM and ODM are both welcome.

We Recommend

New Arrivals

New products from manufacturers at wholesale prices