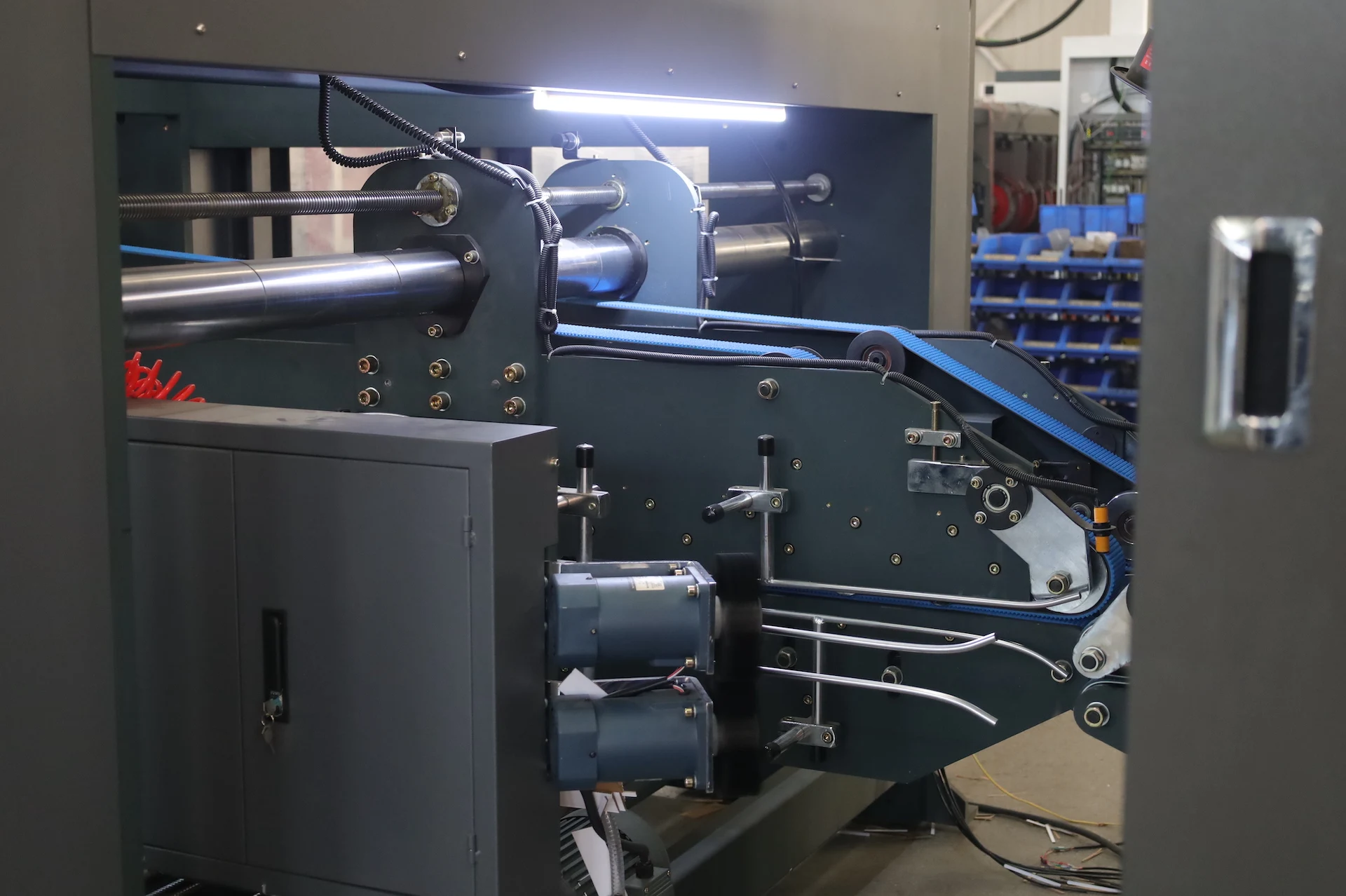

Vacuum Transfer High Definition Flexo Printing Slotting Die Cutting Folding Gluing Strapping Machine FFG

- Category: >>>

- Supplier: Cangzhou Xiaoyuan Carton Machinery Trading Co. Ltd.Cangzhou Ltd.

Share on (1601297934948):

Product Overview

Description

Printing machine unit configuration:

1.The whole machine is designed in strict accordance with the EU CE safety standard, with standardization, universality and humanization. According to the man-machine integrated manufacturing concept, it can directly set, correct, execute, replace, memory and other functions on the touch screen, which is a product with ultra-high cost performance.

2.Touch screen human-machine interface and electric control dual system operation function, with intelligent zero, memory automatic reset, order storage and other functions.

3.The whole machine wall panel and important parts are aging treatment, tempering to eliminate metal internal stress; Are made of high precision machining center, CNC grinding machine grinding processing.

4.The machine shaft and roller are made of high quality steel, grinding, high precision computer dynamic balance correction, the surface is plated with hard chromium.

5.The whole machine transmission gear is made of 40Cr alloy steel, carburized and quenched, hardness HRC58 ~ 62; After grinding, 6-level precision, to ensure long-term use of high color accuracy.

6.The machine transmission parts (shaft, tooth connection),are key-less connection (expansion sleeve), eliminate the connection gap, suitable for large torque long-term high-speed operation.

7.The whole machine transmission bearings, important transmission parts are made of well-known brands: Harbin brand, easy maintenance, longer service life.

8.The lubrication system adopts spray type automatic lubrication and is equipped with automatic balancing device to maintain the same level of oil in each unit.

9.The machine adjusts preset bits. Paper feed, printing, and die-cutting automatically return to zero, and memory automatically resets.

10.The working gap of the machine is adjusted by PLC electric and touch screen. The adjustment is quick, accurate and convenient.

11.The host adopts frequency conversion control, which makes the starting operation more stable and energy saving. Phase adjustment using inverter control, shutdown, operation can be adjusted (PLC touch screen operation).

12.The whole machine is equipped with the function of order storage, which can store 999 orders. According to the carton size, set the parameters of each unit on the touch screen, store the order and give the order number. When the order is produced again, you can search the order number to retrieve and use it, which makes the order exchange more convenient and faster.

13.The machine is equipped with automatic inking function of glue shaft extrusion pressure, and the ink balancing function is turned on by PLC touch screen to manually adjust the pressure between glue shaft and mesh roller. When the photoelectric sensor detects that the pressure of rubber shaft and mesh roller is appropriate, ink will be automatically inking to prevent the printing roller from being polluted directly because the pressure of rubber shaft and mesh roller is too small.

1.The whole machine is designed in strict accordance with the EU CE safety standard, with standardization, universality and humanization. According to the man-machine integrated manufacturing concept, it can directly set, correct, execute, replace, memory and other functions on the touch screen, which is a product with ultra-high cost performance.

2.Touch screen human-machine interface and electric control dual system operation function, with intelligent zero, memory automatic reset, order storage and other functions.

3.The whole machine wall panel and important parts are aging treatment, tempering to eliminate metal internal stress; Are made of high precision machining center, CNC grinding machine grinding processing.

4.The machine shaft and roller are made of high quality steel, grinding, high precision computer dynamic balance correction, the surface is plated with hard chromium.

5.The whole machine transmission gear is made of 40Cr alloy steel, carburized and quenched, hardness HRC58 ~ 62; After grinding, 6-level precision, to ensure long-term use of high color accuracy.

6.The machine transmission parts (shaft, tooth connection),are key-less connection (expansion sleeve), eliminate the connection gap, suitable for large torque long-term high-speed operation.

7.The whole machine transmission bearings, important transmission parts are made of well-known brands: Harbin brand, easy maintenance, longer service life.

8.The lubrication system adopts spray type automatic lubrication and is equipped with automatic balancing device to maintain the same level of oil in each unit.

9.The machine adjusts preset bits. Paper feed, printing, and die-cutting automatically return to zero, and memory automatically resets.

10.The working gap of the machine is adjusted by PLC electric and touch screen. The adjustment is quick, accurate and convenient.

11.The host adopts frequency conversion control, which makes the starting operation more stable and energy saving. Phase adjustment using inverter control, shutdown, operation can be adjusted (PLC touch screen operation).

12.The whole machine is equipped with the function of order storage, which can store 999 orders. According to the carton size, set the parameters of each unit on the touch screen, store the order and give the order number. When the order is produced again, you can search the order number to retrieve and use it, which makes the order exchange more convenient and faster.

13.The machine is equipped with automatic inking function of glue shaft extrusion pressure, and the ink balancing function is turned on by PLC touch screen to manually adjust the pressure between glue shaft and mesh roller. When the photoelectric sensor detects that the pressure of rubber shaft and mesh roller is appropriate, ink will be automatically inking to prevent the printing roller from being polluted directly because the pressure of rubber shaft and mesh roller is too small.

No. | Model | unit | 920 | 1224 | 1426 | 1626 | |||

1 | Maximum speed | pcs/min | 300 | 250 | 250 | 200 | |||

2 | Economic speed | pcs/min | 250 | 220 | 220 | 180 | |||

3 | Max feeding size | mm | 900×2200 | 1200×2600 | 1400×2800 | 1600×2800 | |||

4 | Min feeding size | mm | 300×600 | 350×600 | 400×600 | 450×600 | |||

5 | Max printing size | mm | 900×2000 | 1200×2400 | 1400×2600 | 1600×2600 | |||

6 | Printing roller diameter | mm | 304 | 408 | 480 | 536 | |||

7 | Plate thickness | mm | 3.94 | 3.94 | 3.94 | 3.94 | |||

8 | The thickness | mm | 2-11 | 2-11 | 2-11 | 2-11 | |||

9 | Min slotting distance | mm | 130×130×130×130 | 130×130×130×130 | 130×130×130×130 | 130×130×130×130 | |||

10 | Max slotting distance | mm | 70×210×70×210 | 70×210×70×210 | 70×210×70×210 | 70×210×70×210 | |||

11 | Printing accuracy | mm | +/-0.5 | +/-0.5 | +/-0.5 | +/-0.5 | |||

Automatic folding gluing unit configuration:

This machine is a carton machine developed by our technical team after hard research and according to customer market demand, which can be directly connected with the printing press after printing slotting (die-cutting), gluing, folding, shaping, stacking and counting, and neatly output in one. The machine to save the first printing slotting (die cutting) and then gluing box labor and time, reduce labor intensity and greatly improve the quality of production efficiency for the purpose, the whole machine using PLC full computer control to achieve synchronization with the printing press, size adjustment, order storage, quantity management. Provide you with high speed and high quality production efficiency.

This machine is a carton machine developed by our technical team after hard research and according to customer market demand, which can be directly connected with the printing press after printing slotting (die-cutting), gluing, folding, shaping, stacking and counting, and neatly output in one. The machine to save the first printing slotting (die cutting) and then gluing box labor and time, reduce labor intensity and greatly improve the quality of production efficiency for the purpose, the whole machine using PLC full computer control to achieve synchronization with the printing press, size adjustment, order storage, quantity management. Provide you with high speed and high quality production efficiency.

No. | Model | unit | 920 | 1224 | 1426 | 1626 |

1 | Max stacking height | mm | 350 | 350 | 350 | 350 |

2 | Min stacking height | mm | 80 | 80 | 80 | 80 |

3 | Max stacking | pieces | 30 | 30 | 30 | 30 |

4 | Min stacking | pieces | 15 | 15 | 15 | 15 |

Automatic baler unit configuration:

The automatic baler is an indispensable high-efficiency product after printing in the packaging factory. This product is composed of three modules: paper feeding and finishing department, packaging department and receiving department. It combines traditional mechanical manufacturing with electrical automation to realize easy operation, second order change, maintenance-free.

The automatic baler is an indispensable high-efficiency product after printing in the packaging factory. This product is composed of three modules: paper feeding and finishing department, packaging department and receiving department. It combines traditional mechanical manufacturing with electrical automation to realize easy operation, second order change, maintenance-free.

No. | Max Bundling Size | cm | 140×120×30 | 140×120×30 | 140×120×30 | 140×120×30 |

1 | Min Bundling Size | mm | 400×300×50 | 400×300×50 | 400×300×50 | 400×300×50 |

2 | Min distance C | mm | 300 | 300 | 300 | 300 |

3 | PE tape | mm | 28# | 28# | 28# | 28# |

4 | Speed | package | 18-22(±2) | 18-22(±2) | 18-22(±2) | 18-22(±2) |

5 | Air Perssure | Mpa | 0.8 | 0.8 | 0.8 | 0.8 |

6 | Power | Kw | 4.5 | 4.5 | 4.5 | 4.5 |

7 | Overall dimension | m | 3.9×2.8×2.1 | 3.9×2.8×2.1 | 3.9×2.8×2.1 | 3.9×2.8×2.1 |

8 | Weight | Kg | 1700 | 1700 | 1700 | 1700 |

We Recommend

New Arrivals

New products from manufacturers at wholesale prices