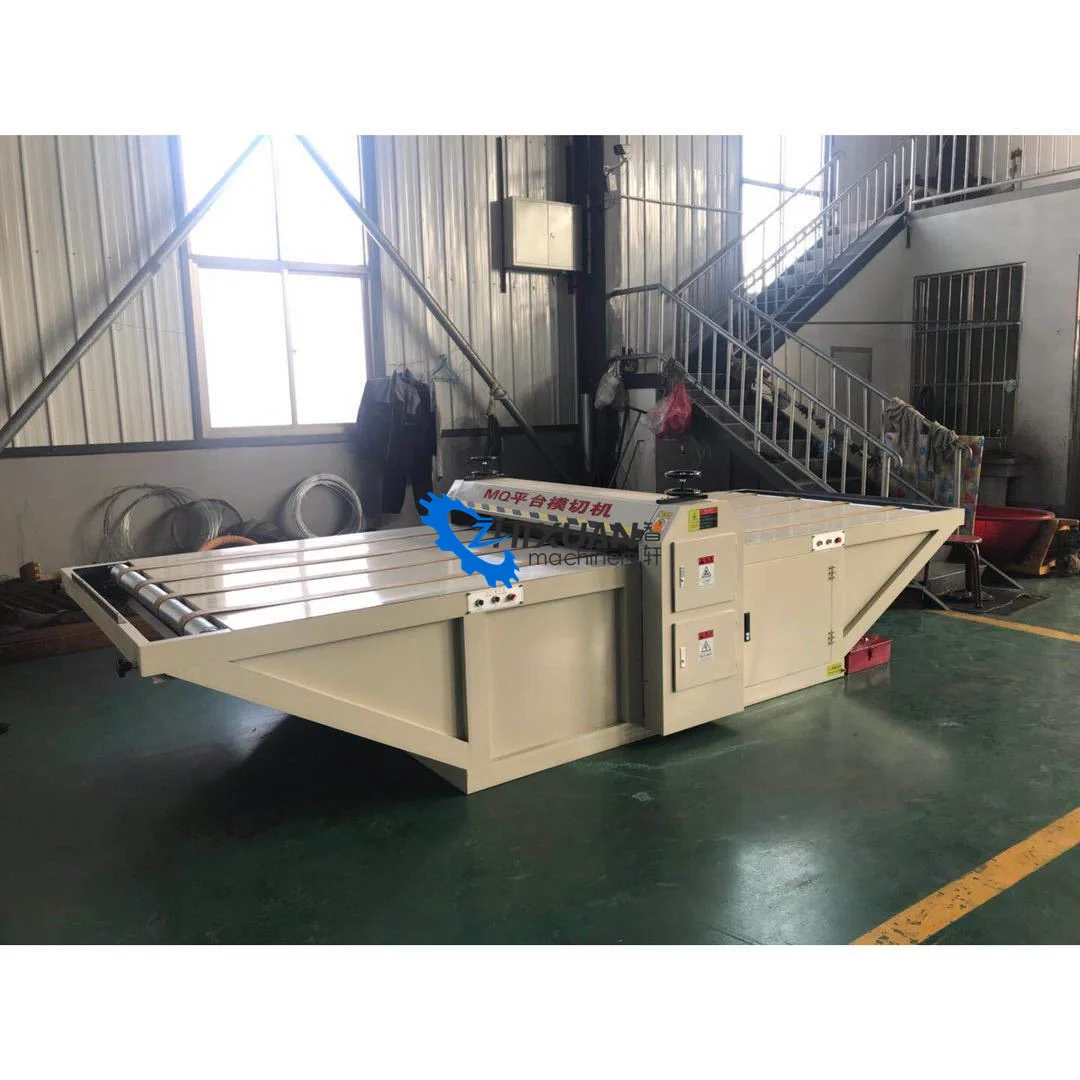

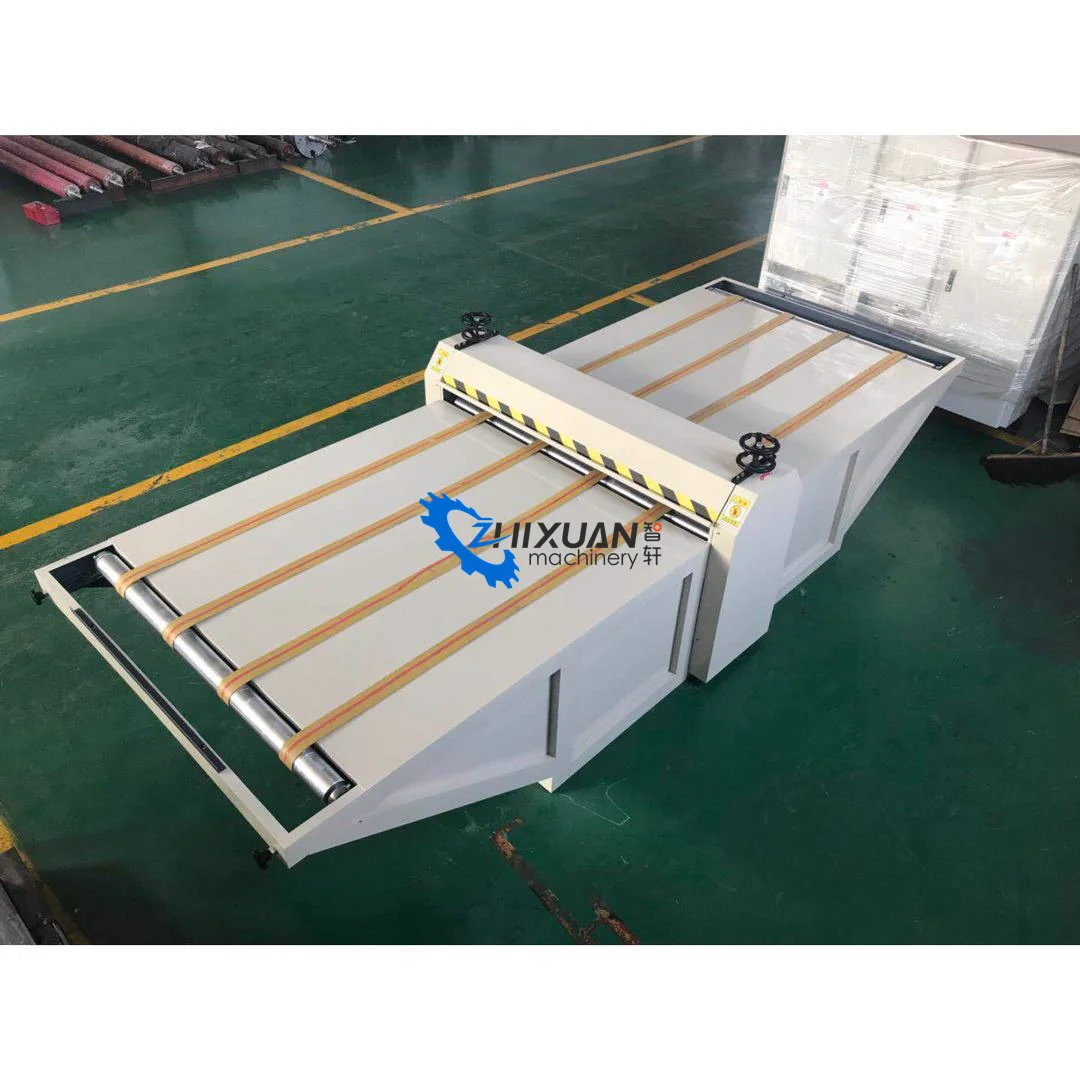

Corrugated Carton Box Die Cutting Machine Die Press Cutting Machine Platform Automatic Positioning Flatbed Die Cutting Machine

- Category: >>>

- Supplier: Henan Zhixuan Machinery Co. Ltd.Henan Ltd.

Share on (1601298344650):

Product Overview

Description

Corrugated Carton Box Die Cutting Machine Die Press Cutting Machine Platform Automatic Positioning Flatbed Die Cutting Machine

Contact person:Angela Wang

Wechat/Whatapps:0086 13676945208

Product Photo

Product Description

Introduction for Platform Automatic Positioning Flatbed Die Cutting Machine:

The Platform Automatic Positioning Flatbed Die Cutting Machine (DIE CUTTING MACHINE) is also called beer machine, cutting machine, CNC punching machine, mainly used for die cutting (full cutting, half cutting), creasing and hot stamping, laminating, automatic waste discharge of some corresponding non-metallic materials, self-adhesive, EVA, double-sided adhesive, electronics, mobile phone rubber pads, etc. The Platform Automatic Positioning Flatbed Die Cutting Machine uses steel knife, hardware mold, steel wire (or template carved from steel plate), and applies a certain pressure through the stamping plate to roll and cut the printed product or cardboard into a certain shape.

The Platform Automatic Positioning Flatbed Die Cutting Machine is an important equipment for post-printing packaging processing and molding.

Main production technology of Platform Automatic Positioning Flatbed Die Cutting Machine

Die-cutting is the most commonly used process for packaging printed materials. It is a molding process that uses a die-cutting knife to combine into a die-cutting plate according to the pattern required by the product design, and under the action of pressure, the printed materials or other coiled blanks are rolled into the required shape or cut marks. The creasing process uses a creasing knife or a creasing die to press out line marks on the sheet material under the action of pressure, or uses a rolling wheel to bend the sheet at a predetermined position. Usually, the die-cutting and creasing process is a process that combines the die-cutting knife and the creasing knife in the same template, and performs die-cutting and creasing processing on the die-cutting machine at the same time, which is referred to as die-cutting. Process introduction The main process of die-cutting and creasing is: plate loading → adjust pressure → determine rules → paste base material and auxiliary materials → test die-cutting → formal die-cutting and creasing → waste removal → finished product winding or cutting into sheets → counting and packaging.

Die-cutting is the most commonly used process for packaging printed materials. It is a molding process that uses a die-cutting knife to combine into a die-cutting plate according to the pattern required by the product design, and under the action of pressure, the printed materials or other coiled blanks are rolled into the required shape or cut marks. The creasing process uses a creasing knife or a creasing die to press out line marks on the sheet material under the action of pressure, or uses a rolling wheel to bend the sheet at a predetermined position. Usually, the die-cutting and creasing process is a process that combines the die-cutting knife and the creasing knife in the same template, and performs die-cutting and creasing processing on the die-cutting machine at the same time, which is referred to as die-cutting. Process introduction The main process of die-cutting and creasing is: plate loading → adjust pressure → determine rules → paste base material and auxiliary materials → test die-cutting → formal die-cutting and creasing → waste removal → finished product winding or cutting into sheets → counting and packaging.

Main Parameter

Platform Automatic Positioning Flatbed Die Cutting Machine | ||||||||||

Model | MQJ-1200 | MQJ-1400 | MQJ-1600 | MQJ-1800 | MQJ-2000 | |||||

Speed | 0-15m/min | 0-15m/min | 0-15m/min | 0-15m/min | 0-15m/min | |||||

Work Size (mm) | 1000x1200 | 1200x1400 | 1300x1500 | 1600x2000 | 1800x12000 | |||||

Power | 1.5kw | 1.5kw | 2.2kw | 2.2kw | 2.2kw | |||||

Weight | 600kg | 650kg | 700kg | 750kg | 1000kg | |||||

Overall Size (mm) | 1500×3000×1250 | 1700×4500×1250 | 1900×4500×1250 | 2100×5000×1250 | 2300x5000x1300 | |||||

Details Images

Related machine

Company Profile

We Recommend

New Arrivals

New products from manufacturers at wholesale prices