Высокое качество автоматической Smt Aoi ZMD 820 мужские водонепроницаемые полностью автоматические автоматическая оптическая контрольно измерительная

- Категория: Electronics Production Machinery >>>

- Поставщик: Shenzhen Morel Electromechanical Equipment Co. Ltd.

Сохранить в закладки 1600409958552:

Описание и отзывы

Характеристики

Products Description

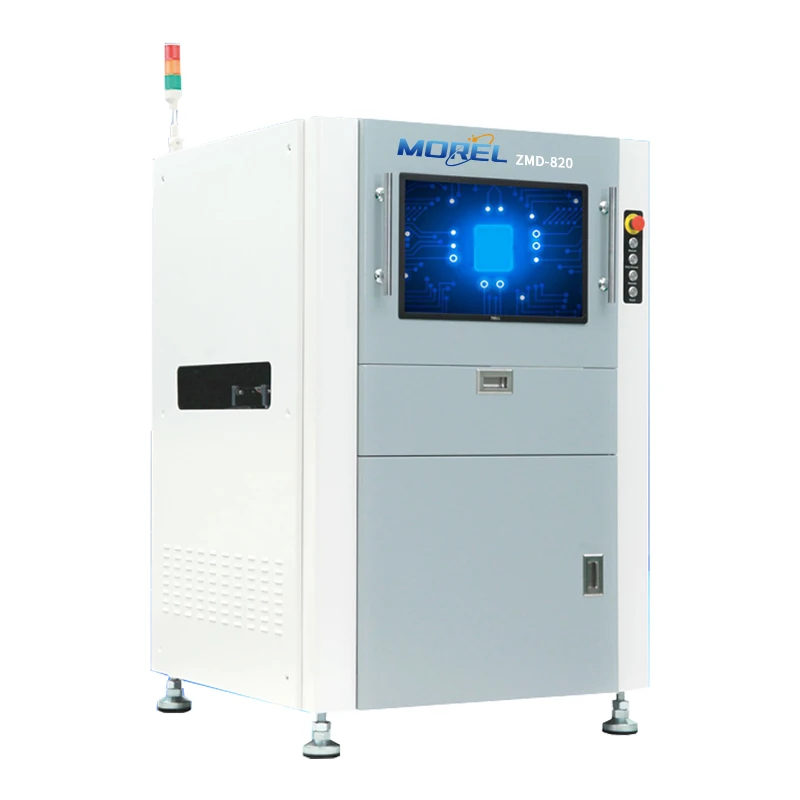

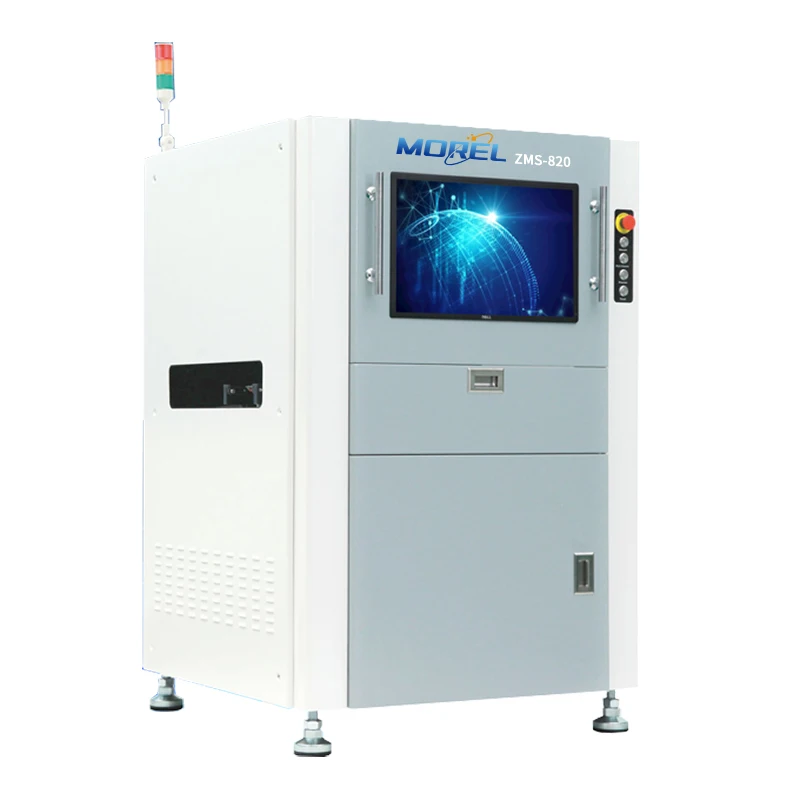

AOI---ZMD-820

The full name of AOI is Automatic Optical Inspection.

It is an intelligent device that detects common defects encountered in welding production based on optical principles/image comparison principles/statistical modeling principles.

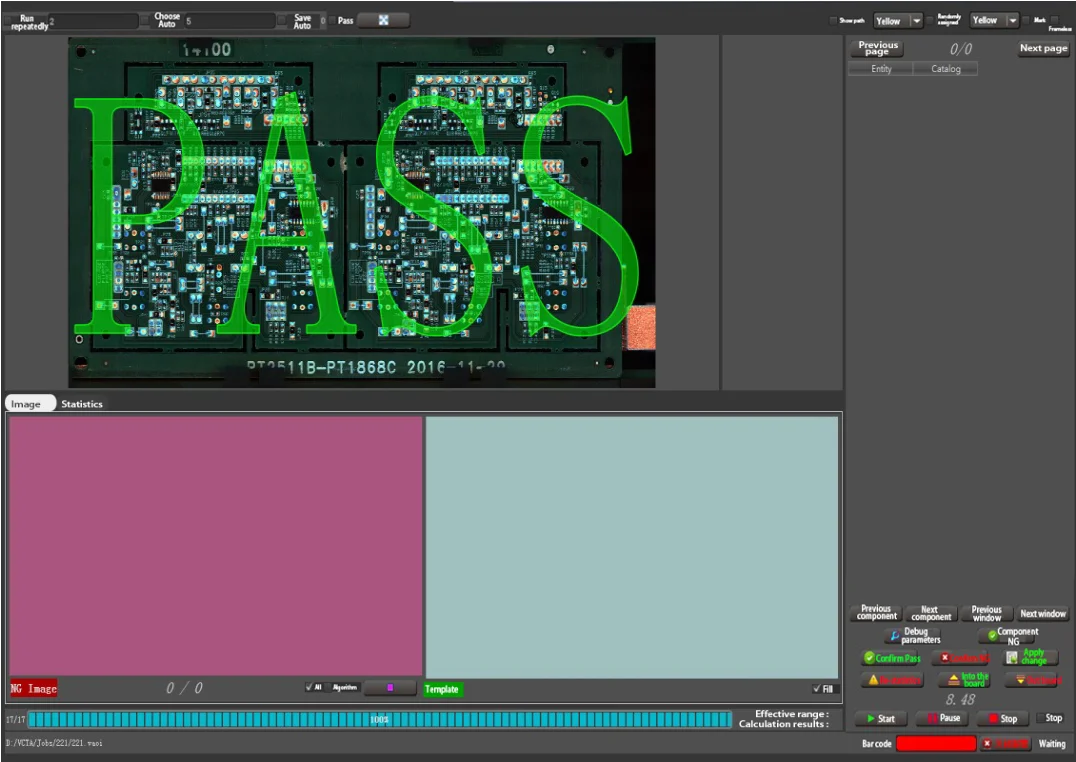

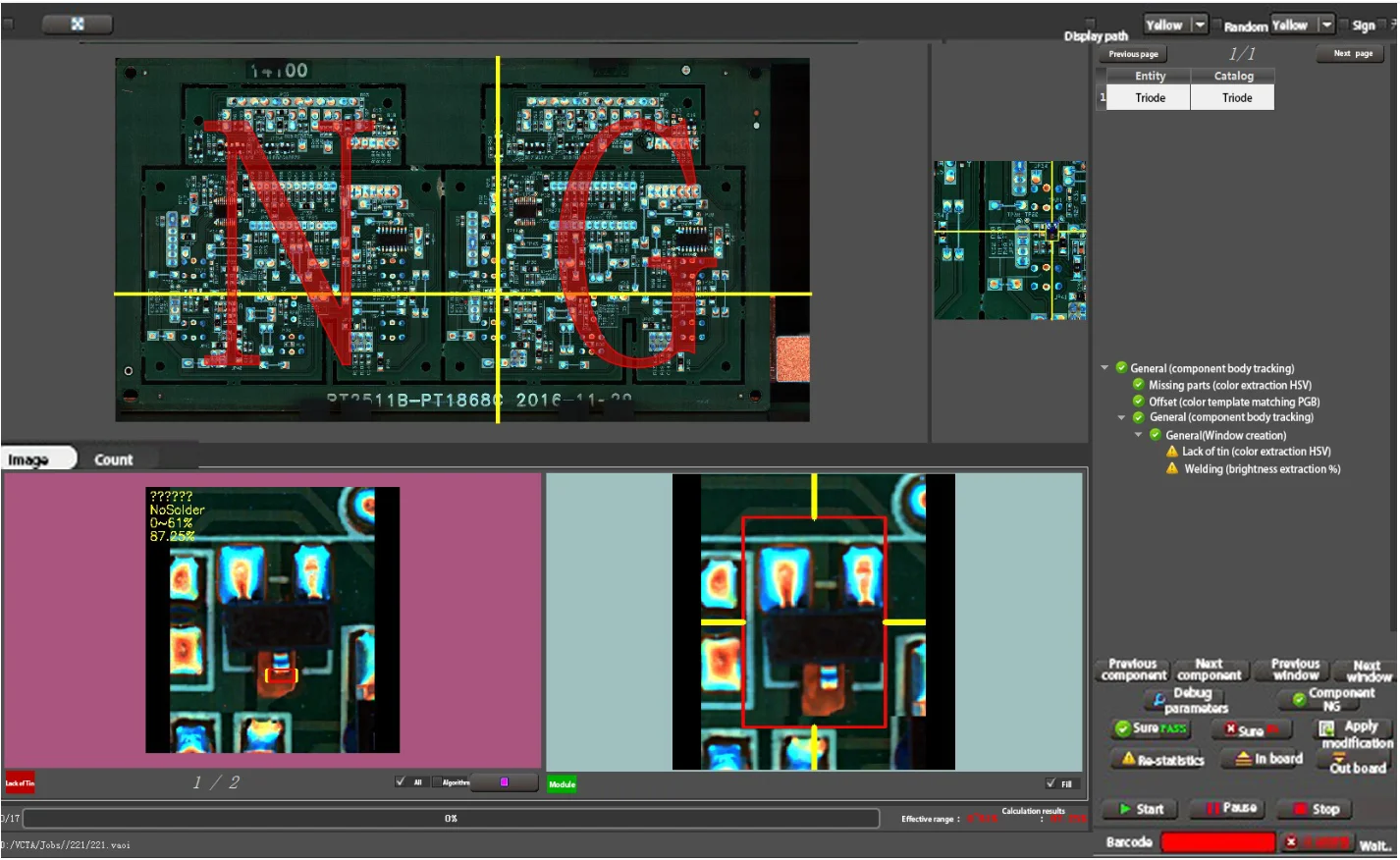

AOI technology can be applied to multiple locations on the production line, of which three inspection locations are the most

representative:

representative:

1) After solder paste printing: The inspection is carried out after the solder paste printing, and defects in the printing process can be found, thereby reducing the soldering defects caused by poor solder paste printing to a minimum.

2) Before reflow soldering: The inspection is done after the components are placed in the solder paste on the board and before the PCB is sent to the reflow oven. This is a typical inspection location because most defects from solder paste printing and machine placement can be found here.

3) After reflow soldering: The biggest advantage of using this solution is that all defects in the manufacturing process can be detected at this stage, so no defects will flow to the end customer.

2) Before reflow soldering: The inspection is done after the components are placed in the solder paste on the board and before the PCB is sent to the reflow oven. This is a typical inspection location because most defects from solder paste printing and machine placement can be found here.

3) After reflow soldering: The biggest advantage of using this solution is that all defects in the manufacturing process can be detected at this stage, so no defects will flow to the end customer.

Details Images

SALES AND SERVICE NETWORK

Company Profile

Morel Equipment Co., Ltd. was established in Shenzhen, the world's SMT center, and has more than 10 years of experience.

It has provided more than 300 medium and large enterprises around the world such as Bosch,Flextronics, Samsung, Vestas, etc. with cost-effective and high-quality products. Morel focuses on providing SMT and Its peripheral equipment, such as placement machines, reflow soldering, printing machines, AOI/SPI, cleaning equipment and other

equipment that meet the requirements of the EMS factory.

equipment that meet the requirements of the EMS factory.

Exhibition

India Exhibition 2013

Thailand Exhibition 2016

Munich Exhibition 2019

China Exhibition 2020

Our Team

Packing and delivery

FAQ

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner

A: One-stop SMT Solution Supplier; Reliable SMT Partner

Q: What your main customers?

A: Huawei, Foxconn, Vtech, Sumida, Kemet, Vishay, Bosch, Canon, Jabil etc.

Q: How to ship and how long it takes?

A: Normally machines will be loaded into a container for sea shipment. In case of urgency, Air Cargo is an option (shipping cost will increase significantly). It takes 15-50 days depend on destined ports which for Air Cargo it is about 3-10 Days depend on destined airports.

A: Huawei, Foxconn, Vtech, Sumida, Kemet, Vishay, Bosch, Canon, Jabil etc.

Q: How to ship and how long it takes?

A: Normally machines will be loaded into a container for sea shipment. In case of urgency, Air Cargo is an option (shipping cost will increase significantly). It takes 15-50 days depend on destined ports which for Air Cargo it is about 3-10 Days depend on destined airports.

Q:How is the warranty works?

A:Every unit of machines has been thoroughly inspected, calibrated to make sure they are ready to go status right after been installed on the customer side. But in rare cases like damages or electric failure caused by transport, bellows are what we are going to do to fix:

1. Experience engineer will work with customers to find out the problems and conclude the solution.

2. Parts will be sent for replacement within the warranty period at our cost and an engineer will be deployed to the customer site to help with machines fixing in case of the customer cannot fix it by themselves. In the case of our engineer service, there is a fee occurred.

Q: How to make payment?

A: We accept Wire transfer through bank, West Union, Credit card (Only through PayPal, additional 4.5% fee will be charge), and sometimes by L/C for special cases.

A:Every unit of machines has been thoroughly inspected, calibrated to make sure they are ready to go status right after been installed on the customer side. But in rare cases like damages or electric failure caused by transport, bellows are what we are going to do to fix:

1. Experience engineer will work with customers to find out the problems and conclude the solution.

2. Parts will be sent for replacement within the warranty period at our cost and an engineer will be deployed to the customer site to help with machines fixing in case of the customer cannot fix it by themselves. In the case of our engineer service, there is a fee occurred.

Q: How to make payment?

A: We accept Wire transfer through bank, West Union, Credit card (Only through PayPal, additional 4.5% fee will be charge), and sometimes by L/C for special cases.

Q: Why choose you?

A: Leading SMT Supplier in China; Professional Supplier on Alibaba; Professional after-sales service team.

Certifications

Похожие товары

YS-805A машина для отделения печатных плат

Прямая продажа с завода, настольный робот для автоматической дозирования клея

1 550,00 $ - 1 800,00 $

NTL-300 CUH электромагнитный линейный Фидер привод база точность малый размер

Монтажная машина Smt, модель S10 Smt более высокого качества, машина для установки и установки в линии Smt

Hecan поверхностного монтажа машина вертикальная HC-H4 автоматическая SMT производственная линия сборки печатных плат SMT линии SMT трафарет машины

8 300,00 $ - 8 500,00 $

Многофункциональная машина для монтажа микросхем Hanwha SM482 Plus

Система дозирования клея с ЖК-дисплеем, автоматическая дозирующая машина для жидкости, Малайзия, 1 год, онлайн-Поддержка двигателя PLC

Новые поступления

Новинки товаров от производителей по оптовым ценам

Умный цифровой электронный ручной инфракрасный лазерный термометр для ветеринарного и медицинского мониторинга человека

5-10 $

Цифровой инфракрасный лазерный термометр для взрослых

5,90-6,70 $

Командная версия 24-скоростной ультралегкий карбоновый шоссейный велосипед Гоночная рама и комплект колес

Четырехцилиндровый двигатель CA6110/125G5 части клапана 1007011-A013-0000 1007016-A013-0000

0,50 $

55203781 46740344 55181201 55266538 зубчатый шкив коленчатого вала для FIAT 500 BRAVA BRAVO DOBLO PANDA PUNT0

3-3,70 $

Оптовая продажа 100% Рафинированное Масло из семян подсолнечника малазия масло для приготовления пищи

GY031 металлическая рамка пользовательских игровых сидений Sim гоночные игровые сиденья симулятор вождения кабины для Xbox 360 Logitech G25 G27 G29 G920

88-143 $

Роскошные пользовательские островные стулья современные кухонные с выдвижными ящиками и раковиной кухонный шкаф U-образной формы из нержавеющей стали

160-180 $